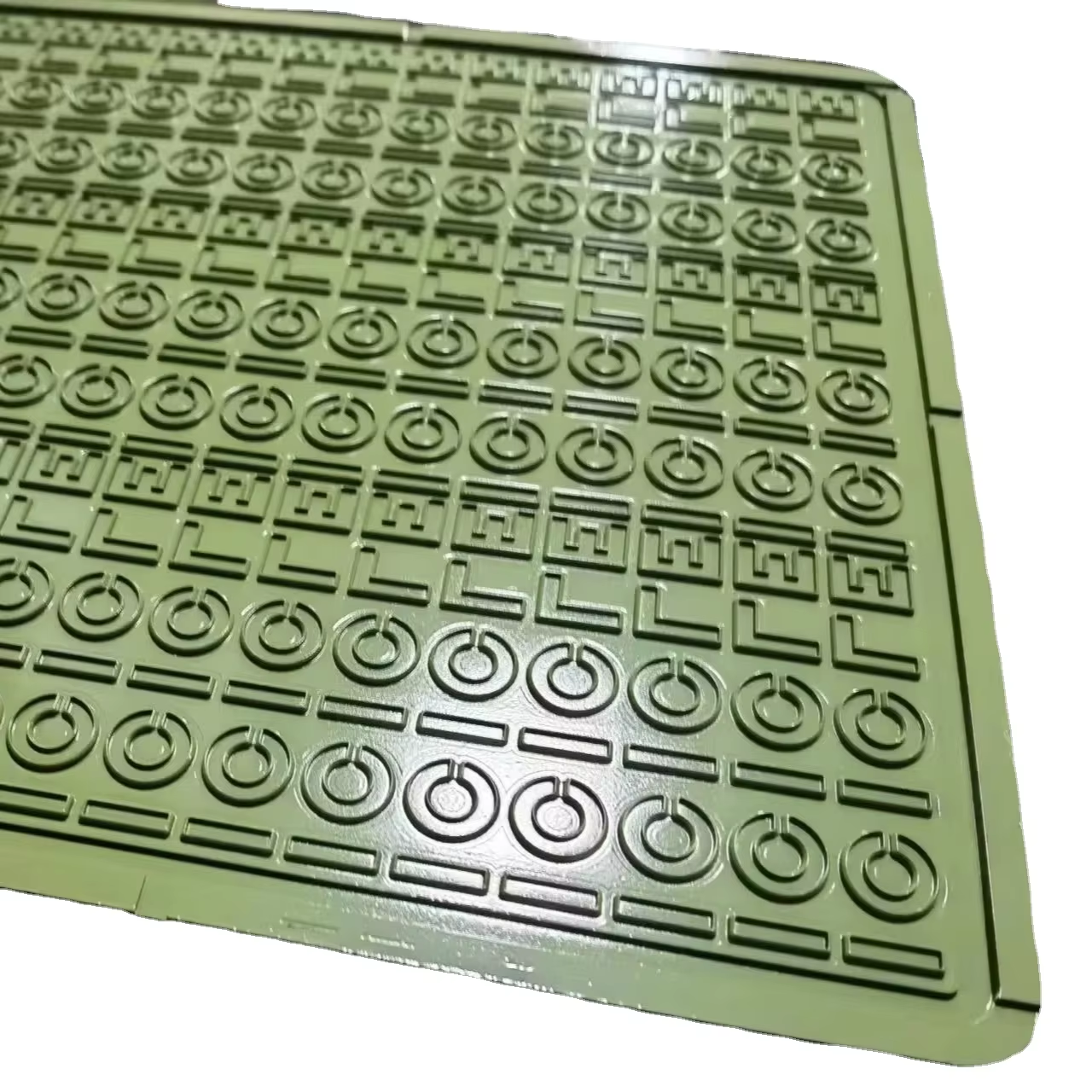

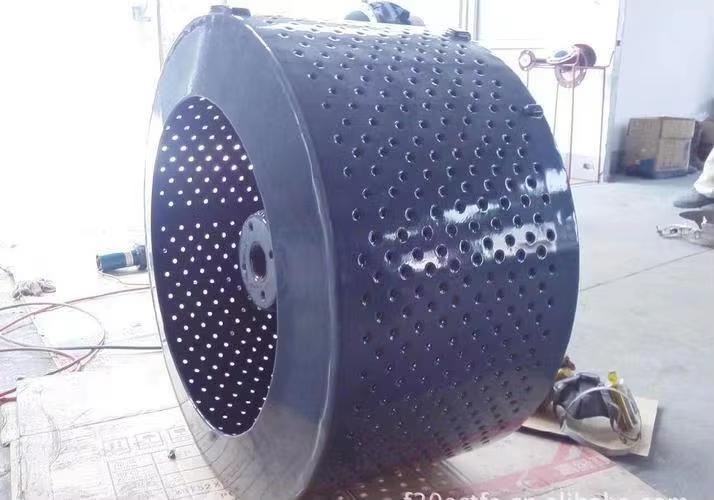

Easy release PTFE non stick coating is a game - changing innovation in the world of surface coatings, offering unparalleled non - stick properties that simplify manufacturing and processing operations. Engineered with precision, this easy release PTFE non stick coating is formulated to provide a smooth and slippery surface that enables effortless separation of materials from coated surfaces. In the manufacturing of plastic products, for instance, when using molds to shape plastics through injection molding or blow molding processes, the easy release PTFE non stick coating on the mold surfaces ensures that the finished plastic parts can be removed with minimal force. This not only reduces the risk of damage to the delicate plastic parts during demolding but also significantly increases the production speed as the cycle time between mold fills and part removal is shortened. In the rubber and silicone molding industries, where the materials can be sticky and difficult to release from molds, the easy release PTFE non stick coating proves invaluable. It allows for seamless separation of rubber or silicone products, whether they are gaskets, seals, or intricate molded components, without leaving behind any residue on the mold. This helps in maintaining the quality of the molds and reduces the need for frequent mold cleaning and maintenance. In the food processing industry, easy release PTFE non stick coating is widely used on baking pans, trays, and cooking utensils. It ensures that baked goods like bread, cakes, and cookies can be easily removed from the pans, resulting in clean - looking products with no sticking or tearing. This also simplifies the cleaning process as there is less food residue to scrub off, saving time and effort in the kitchen. The easy release PTFE non stick coating is designed to be highly durable, maintaining its non - stick properties even after repeated use and exposure to various environmental conditions. It can withstand high temperatures, which is beneficial in applications such as industrial baking or cooking where the coated surfaces are subjected to intense heat. Moreover, the coating offers good chemical resistance, protecting the underlying substrate from corrosion caused by cleaning agents, food acids, or industrial chemicals. The application of easy release PTFE non stick coating involves advanced techniques to ensure a uniform and thin layer is applied, which maximizes the non - stick performance while minimizing any potential impact on the functionality of the substrate. Whether in manufacturing, food service, or other industries where the easy release of materials is crucial, this PTFE non stick coating provides a reliable and efficient solution.