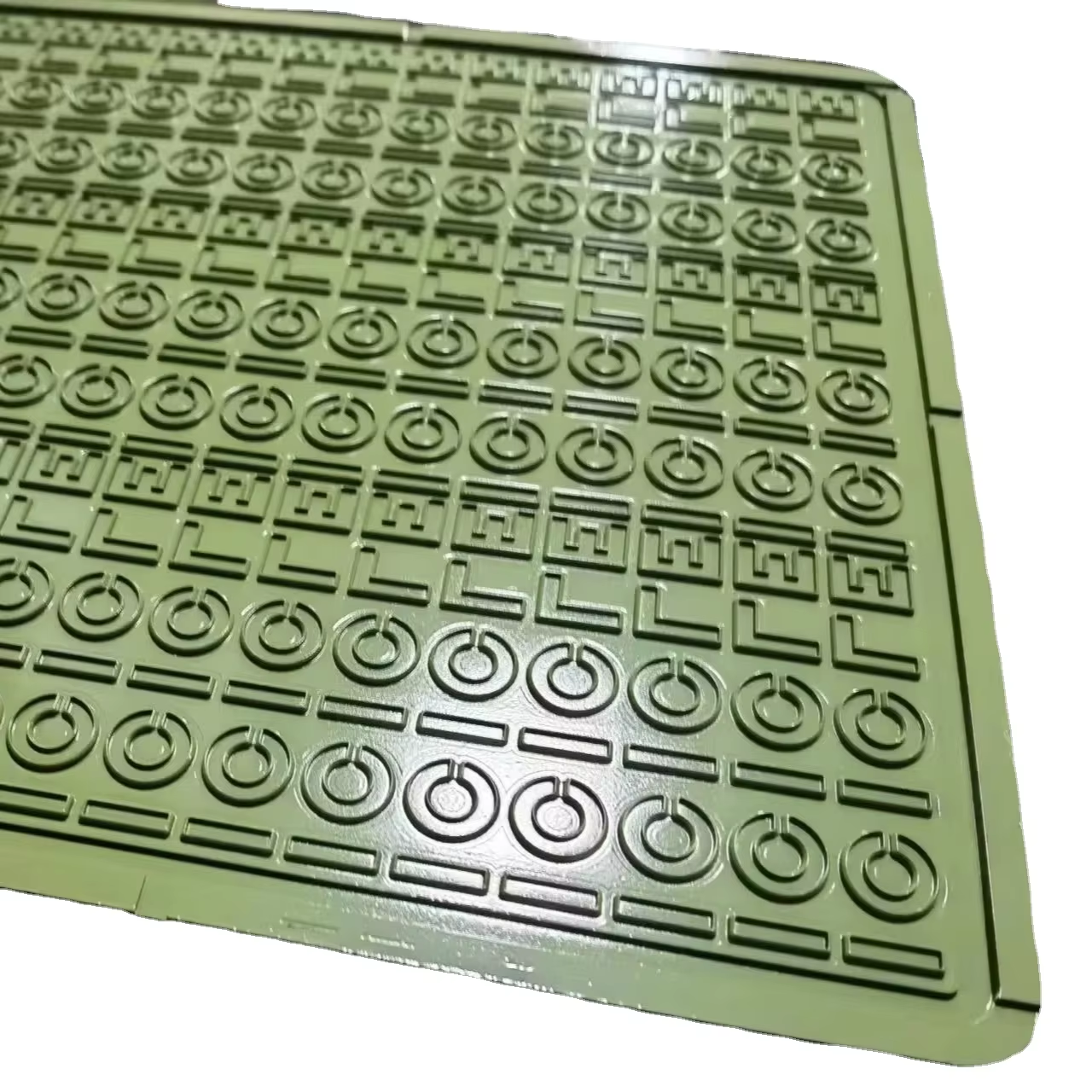

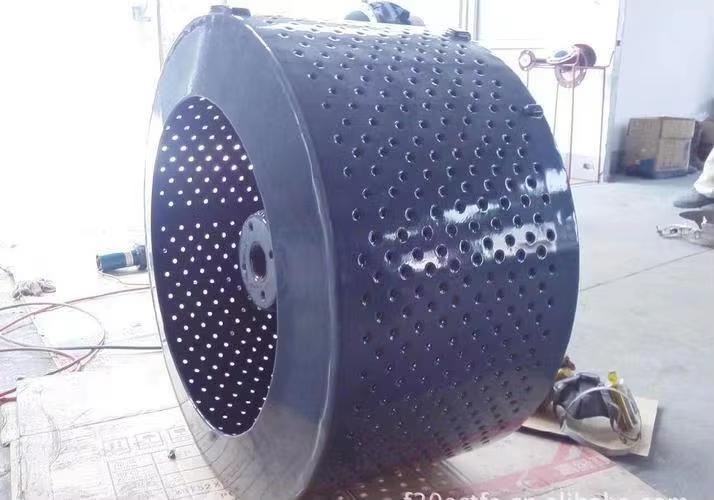

PTFE non stick coating for metal is a transformative solution that enhances the functionality and longevity of metal surfaces by combining the strength and durability of metal with the exceptional non-stick properties of PTFE. This PTFE non stick coating for metal forms a strong, uniform bond with various metal substrates, including steel, aluminum, and stainless steel, creating a smooth, low-friction surface that resists adhesion of oils, greases, food residues, and industrial contaminants. PTFE non stick coating for metal is widely used in kitchenware, where metal pans, pots, and baking trays coated with this formulation ensure easy food release, reduce the need for excessive oil, and simplify cleaning, all while withstanding high cooking temperatures. In industrial settings, PTFE non stick coating for metal protects metal components such as conveyor belts, chutes, and molds from corrosion caused by chemicals, moisture, and environmental factors, extending their service life and reducing maintenance costs. PTFE non stick coating for metal also minimizes friction between moving metal parts, such as gears and bearings, improving energy efficiency and reducing wear and tear in machinery. The application process for PTFE non stick coating for metal involves surface preparation to ensure optimal adhesion, followed by precise techniques like spray coating or electrostatic deposition, resulting in a durable layer that can withstand repeated use and thermal cycling. This PTFE non stick coating for metal is available in formulations tailored to specific metal types and applications, with some variants offering enhanced heat resistance up to 260°C, making them suitable for high-temperature industrial processes. Whether used in consumer goods or heavy machinery, PTFE non stick coating for metal delivers a winning combination of metal’s structural integrity and PTFE’s non-stick performance, making it an essential solution for diverse metal surface treatment needs.