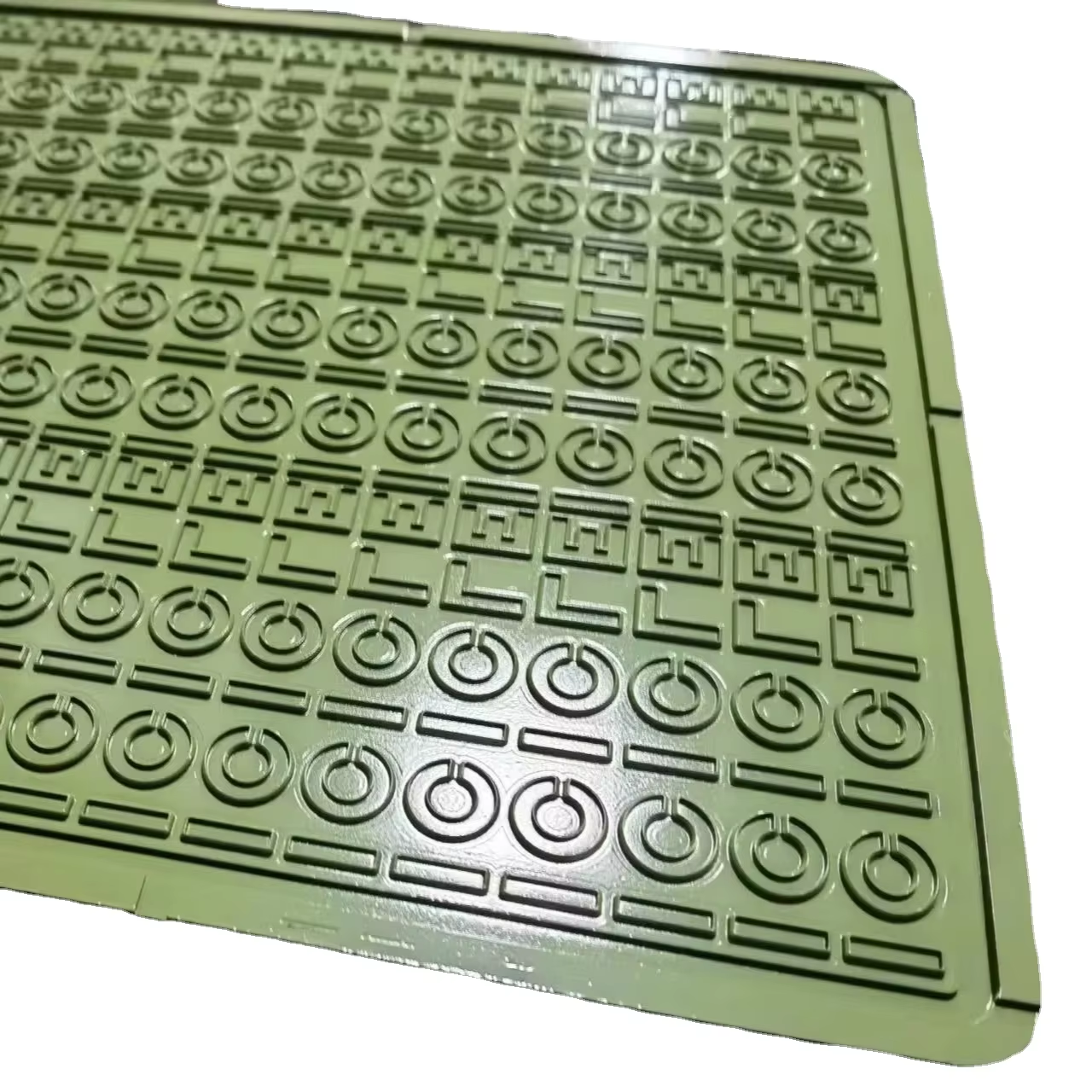

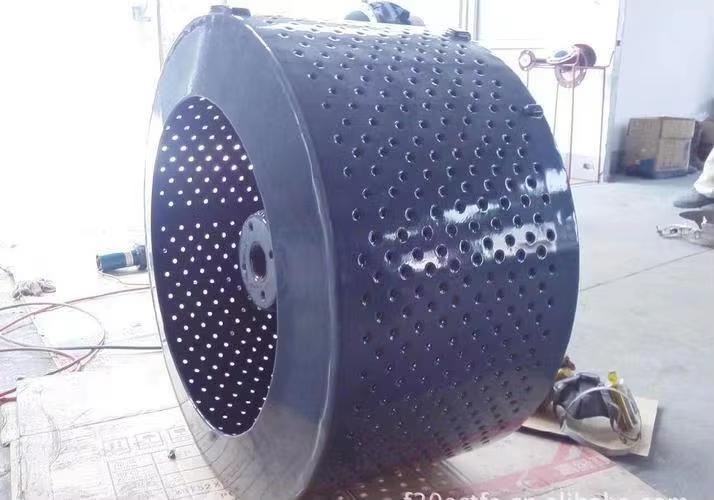

High adhesion PTFE non stick coating is a specialized formulation designed to form a strong, long-lasting bond with diverse substrates, ensuring that the coating remains intact even under extreme conditions such as high temperatures, mechanical stress, and exposure to corrosive substances. This high adhesion PTFE non stick coating addresses the common challenge of PTFE’s natural low surface energy, which can hinder bonding, by incorporating advanced primers or modifiers that enhance its ability to adhere to metals, plastics, ceramics, and rubber. In industrial settings, high adhesion PTFE non stick coating is essential for machinery components like gears, bearings, and conveyor belts, where the coating must withstand friction and vibration without peeling or flaking, ensuring consistent non-stick performance and reducing maintenance downtime. For molds used in rubber, silicone, or latex production, high adhesion PTFE non stick coating ensures that the coating stays firmly attached to the mold surface through repeated cycles of heating, cooling, and part release, preserving the mold’s integrity and extending its service life. High adhesion PTFE non stick coating also excels in kitchenware applications, where it bonds securely to metal pans and pots, resisting damage from metal utensils and repeated cleaning while maintaining its non-stick properties. In chemical processing equipment, this high adhesion PTFE non stick coating provides a reliable barrier against corrosive fluids, as its strong bond prevents the coating from lifting and exposing the substrate to damage. The application of high adhesion PTFE non stick coating involves precise surface preparation, such as grit blasting or chemical etching, to maximize substrate contact, followed by controlled curing to activate the adhesion promoters. This results in a coating that combines the best of PTFE’s non-stick, chemical resistance, and heat resistance with enhanced adhesion, making high adhesion PTFE non stick coating a versatile solution for demanding applications where coating longevity is paramount.