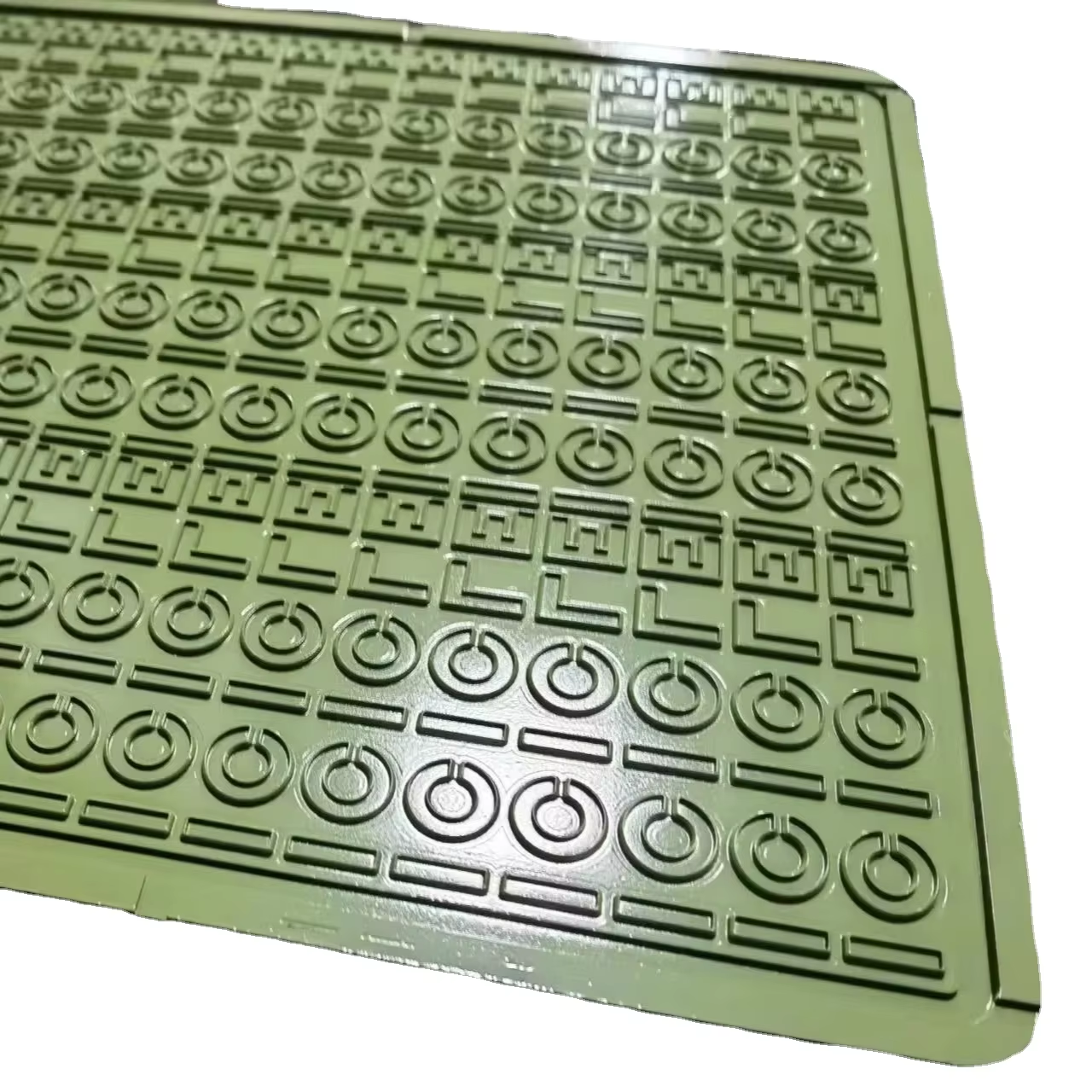

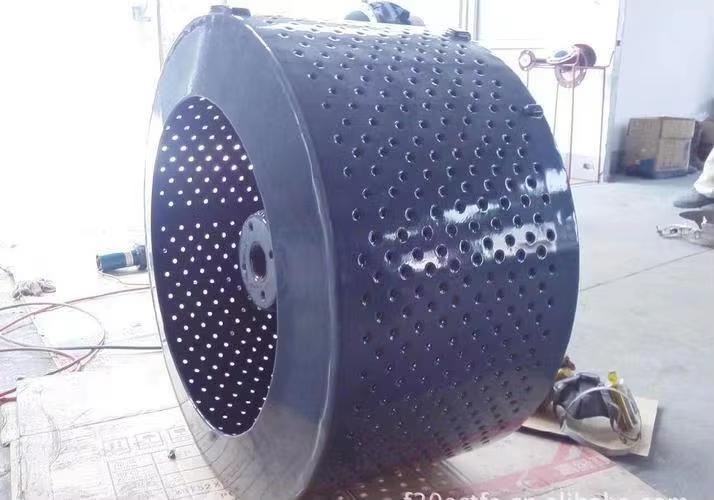

Teflon coating for industrial use is a versatile and high-performance solution designed to address the rigorous demands of manufacturing, chemical processing, and heavy machinery operations. This teflon coating for industrial use offers a unique blend of properties, including exceptional non-stick performance, high-temperature resistance up to 260°C, and broad chemical inertness, making it suitable for a wide range of industrial applications. In machinery, teflon coating for industrial use reduces friction between moving parts like gears, bearings, and conveyor belts, minimizing energy consumption and wear, thus extending equipment lifespan. For chemical processing equipment—such as tanks, pipes, and valves—teflon coating for industrial use provides a protective barrier against corrosive acids, alkalis, and solvents, preventing degradation and ensuring the purity of processed materials. Teflon coating for industrial use is also ideal for molds used in rubber, silicone, and latex production, facilitating easy release of parts and reducing the need for release agents, which streamlines production. Its durability allows it to withstand harsh industrial environments, including exposure to dust, moisture, and mechanical stress, without peeling or losing functionality. Available in water-based formulations, teflon coating for industrial use aligns with eco-friendly manufacturing practices by reducing VOC emissions. Whether applied to metal, ceramic, or composite substrates, teflon coating for industrial use delivers reliable performance, lowering maintenance costs and improving operational efficiency across diverse industrial sectors.