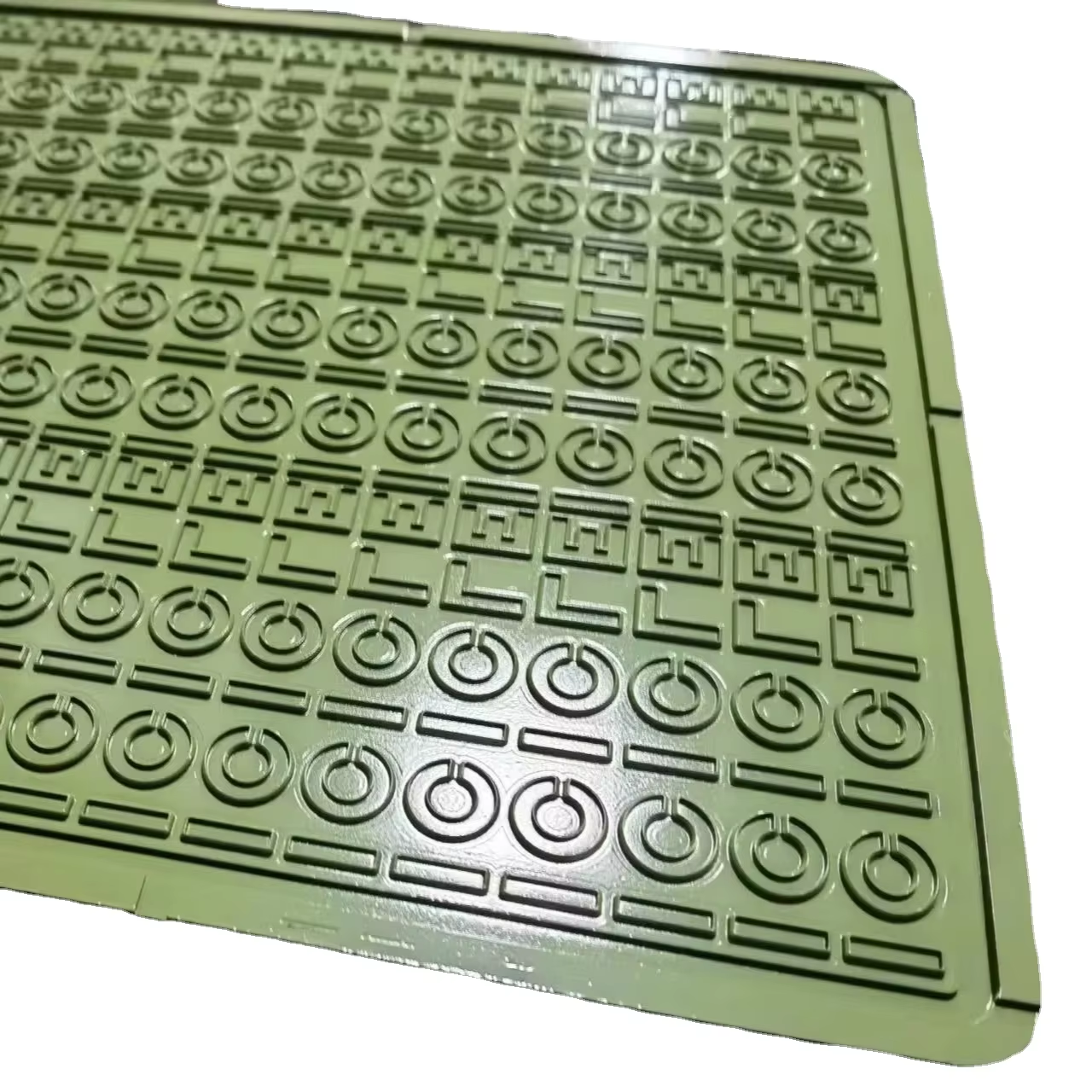

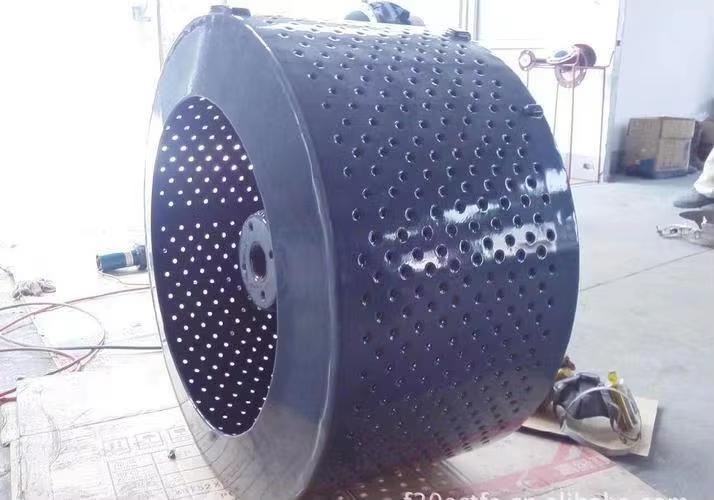

PTFE non stick coating for valves is a game-changing solution in fluid control systems, enhancing valve performance by reducing friction, preventing buildup, and protecting against corrosion, ensuring smooth operation and extended service life. This PTFE non stick coating for valves is applied to critical valve components such as stems, seats, discs, and housings, creating a smooth surface that minimizes friction between moving parts, allowing for precise, effortless actuation even after prolonged use. In the chemical industry, where valves handle aggressive acids, alkalis, and solvents, PTFE non stick coating for valves provides exceptional chemical resistance, preventing corrosion and ensuring that the valve maintains a tight seal, reducing the risk of leaks that could lead to safety hazards or product contamination. PTFE non stick coating for valves also resists the buildup of scale, sludge, and viscous fluids, which is crucial in applications like oil and gas processing or water treatment, where deposits can impede flow and cause valve sticking. For high-temperature systems, such as those in power generation or industrial heating, PTFE non stick coating for valves withstands elevated temperatures without degrading, maintaining its non-stick and protective properties. The coating’s low friction 特性 of PTFE non stick coating for valves reduces wear on valve components, extending their lifespan and reducing the need for frequent replacements. Additionally, PTFE non stick coating for valves simplifies maintenance, as the non-stick surface makes cleaning easier, ensuring that valves can be restored to optimal performance quickly. Whether used in ball valves, gate valves, or butterfly valves, PTFE non stick coating for valves is a reliable solution that improves efficiency, safety, and durability in fluid control systems across industries.