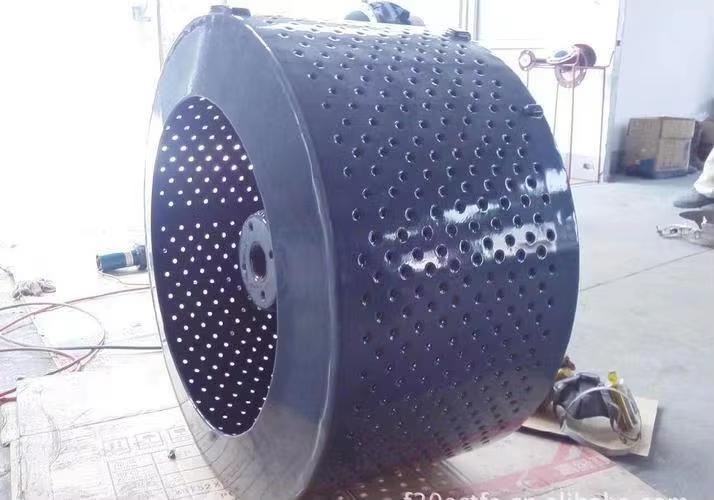

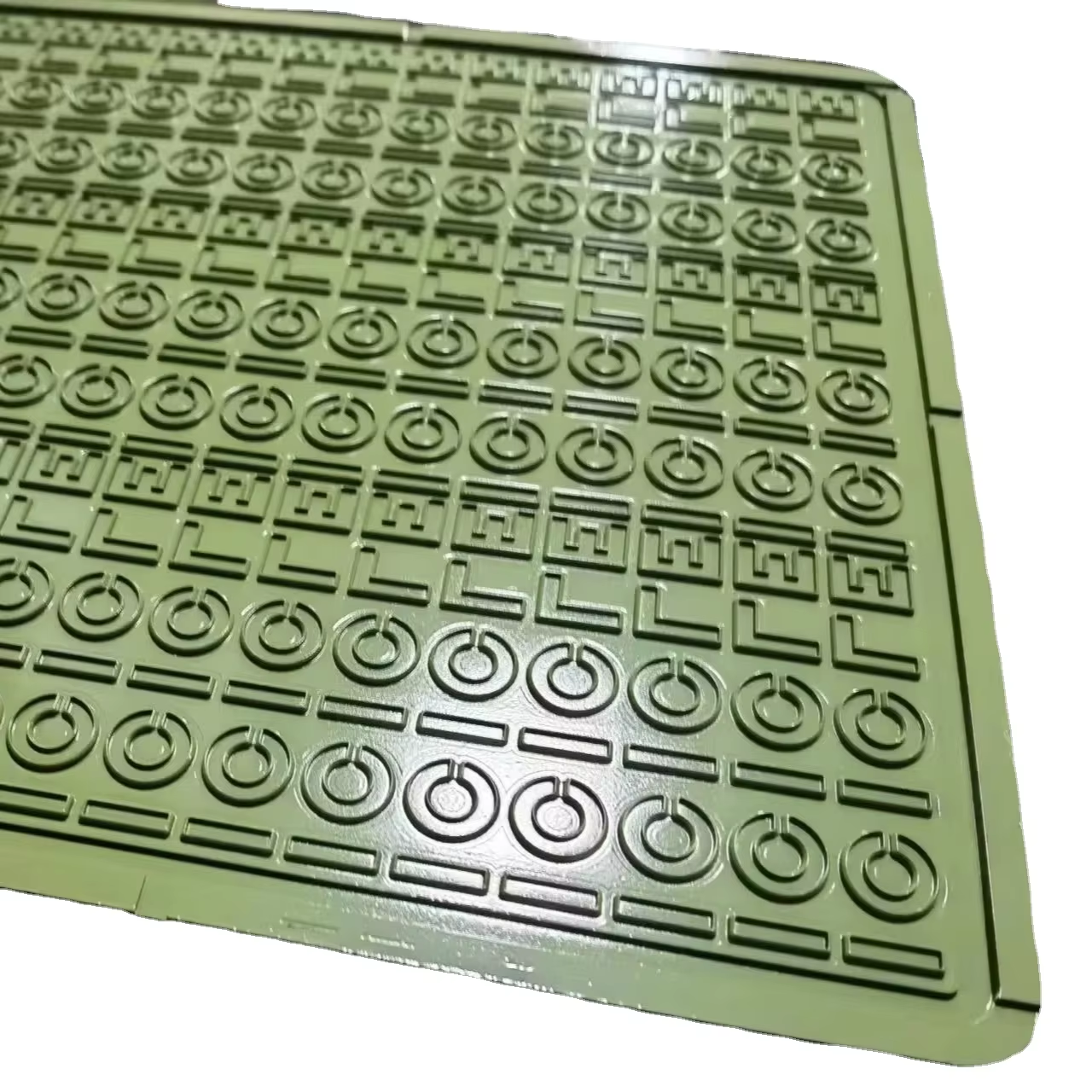

PTFE non stick coating for rubber is a highly specialized solution designed to revolutionize the manufacturing and performance of rubber products across a wide spectrum of industries. This PTFE non stick coating for rubber is engineered to bond firmly with rubber surfaces, forming an ultra-smooth, low-friction layer that significantly reduces adhesion of various substances to the rubber. In the production of rubber molds, PTFE non stick coating for rubber ensures that the cured rubber parts release easily from the mold, minimizing the risk of damage to the delicate rubber components during demolding. This not only improves the production efficiency but also enhances the quality of the final rubber products by preventing surface imperfections caused by sticking. For rubber gaskets and seals, PTFE non stick coating for rubber offers enhanced resistance to wear and tear, as well as protection against chemical corrosion, which is crucial in applications where the rubber components are exposed to aggressive fluids or high temperatures. PTFE non stick coating for rubber also provides excellent release properties in the production of rubber conveyor belts, ensuring that materials being transported do not adhere to the belt surface, thus maintaining smooth operation and reducing the need for frequent cleaning. The application of PTFE non stick coating for rubber involves advanced techniques to ensure uniform coverage, even on complex rubber shapes, and to create a durable bond that withstands the mechanical stresses and environmental conditions typically encountered by rubber products. This PTFE non stick coating for rubber is formulated to meet strict industry standards for safety and performance, making it a reliable choice for manufacturers seeking to optimize the functionality and lifespan of their rubber-based products, whether in automotive, industrial, or consumer goods applications.