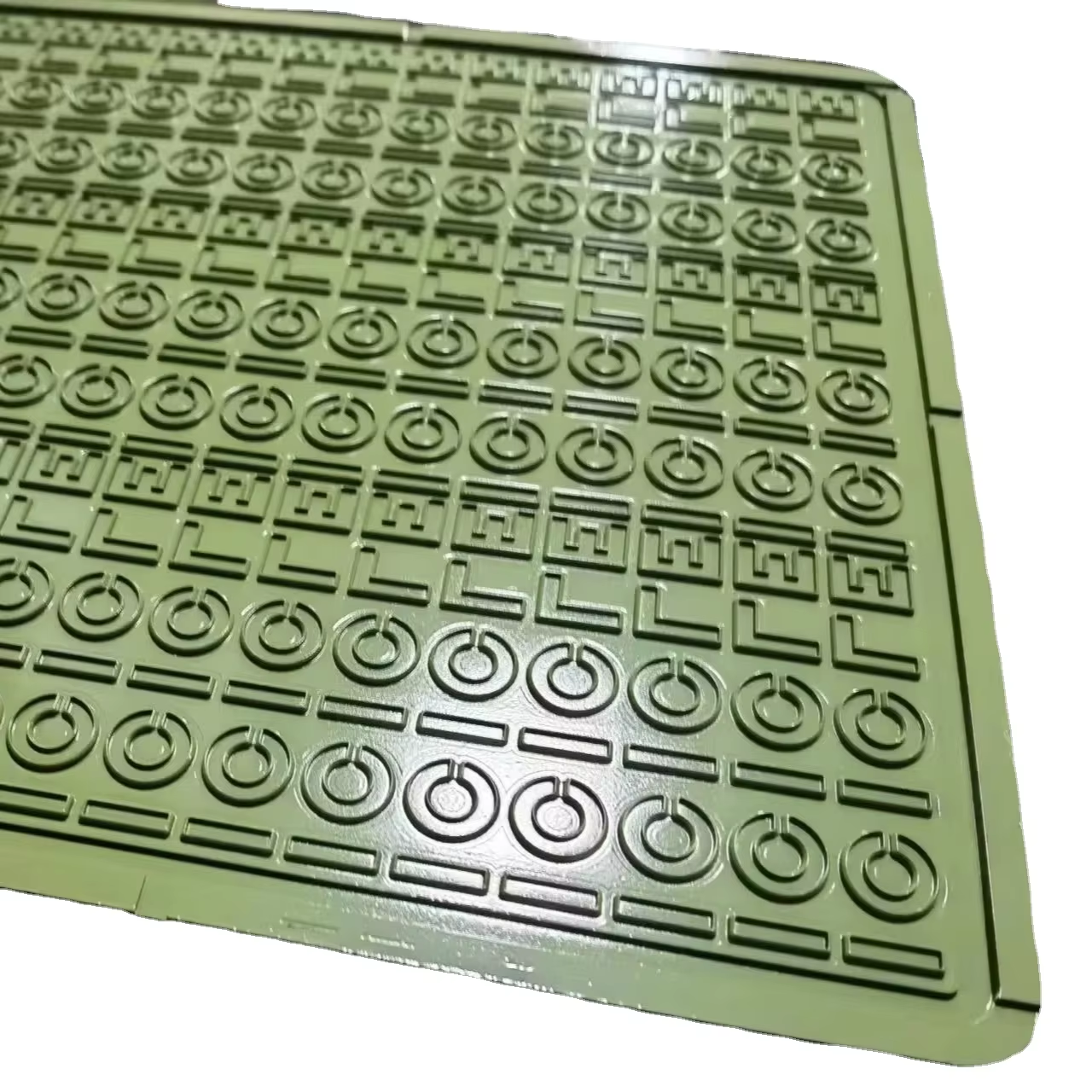

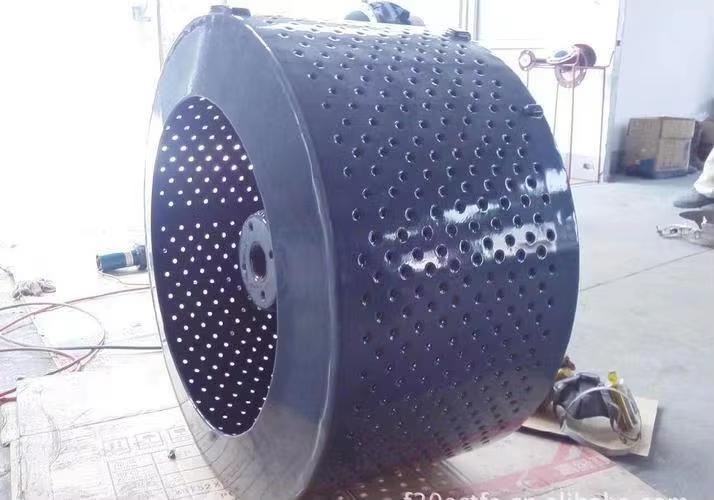

PTFE non stick coating in chemical industry is a critical solution that addresses the unique challenges of handling aggressive substances, high temperatures, and corrosive environments. In chemical processing, PTFE non stick coating in chemical industry creates a protective barrier on equipment such as reaction vessels, pipes, valves, and agitators, preventing the adhesion of corrosive chemicals, viscous fluids, and solid residues, which simplifies cleaning and reduces the risk of cross-contamination. This PTFE non stick coating in chemical industry exhibits exceptional resistance to a wide spectrum of chemicals, including strong acids, alkalis, solvents, and oxidizing agents, ensuring that the underlying metal or composite substrates remain unharmed, thus extending equipment lifespan and reducing maintenance costs. PTFE non stick coating in chemical industry also withstands the high temperatures often encountered in chemical reactions and distillation processes, maintaining its non-stick properties even under thermal stress, which is crucial for maintaining process efficiency. In addition, the low friction 特性 of PTFE non stick coating in chemical industry minimizes fluid resistance in pipes and channels, improving flow rates and reducing energy consumption. For batch processing, PTFE non stick coating in chemical industry enables easy release of reaction by-products, ensuring thorough emptying of vessels and reducing waste. It also complies with strict industry standards for purity, as it does not leach contaminants into the chemicals being processed, making it suitable for pharmaceutical and food-grade chemical production. Whether applied to large-scale industrial reactors or small laboratory equipment, PTFE non stick coating in chemical industry is a versatile and reliable solution that enhances operational efficiency and safety.