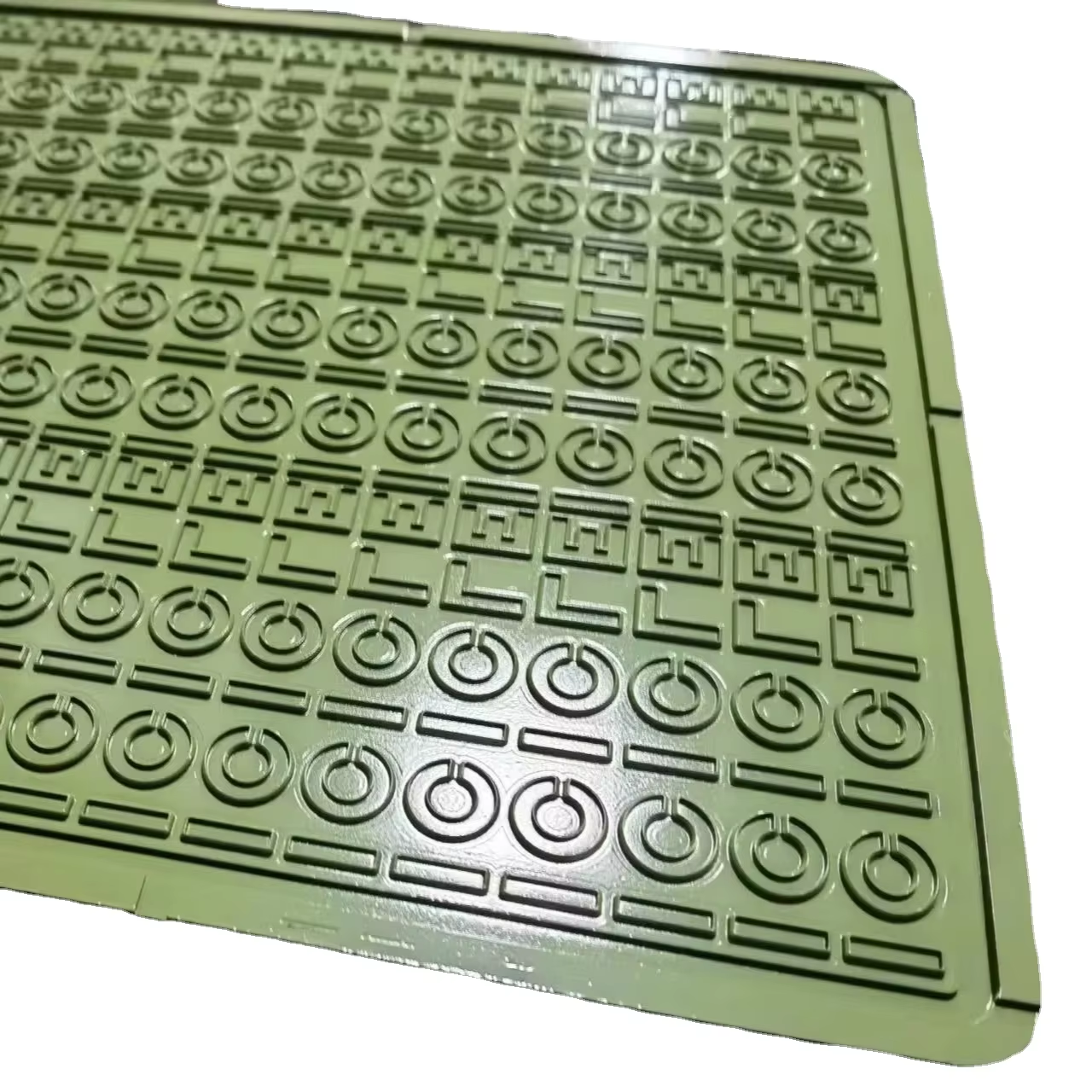

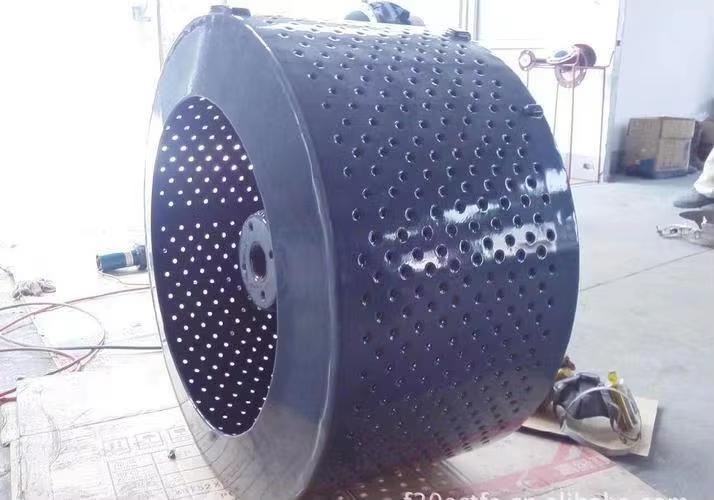

Industrial PTFE non stick coating is a high-performance solution tailored to meet the rigorous demands of industrial environments, where reliability, durability, and resistance to harsh conditions are paramount. This industrial PTFE non stick coating is formulated to provide exceptional non-stick properties on a variety of industrial substrates, including metals, ceramics, and certain composites, ensuring that materials such as adhesives, resins, and industrial fluids do not adhere to surfaces, thus reducing downtime and maintenance costs. Industrial PTFE non stick coating is widely used in machinery manufacturing, where it is applied to components like conveyor belts, chutes, and molds, facilitating the smooth movement of materials and easy release of manufactured parts, which in turn enhances production efficiency. In the chemical industry, industrial PTFE non stick coating plays a crucial role in protecting equipment such as reaction vessels, pipes, and valves from corrosion caused by aggressive chemicals, acids, and solvents, ensuring the integrity of the equipment and the purity of the chemicals being processed. This industrial PTFE non stick coating also exhibits excellent high-temperature resistance, making it suitable for use in high-heat industrial processes, such as those found in the automotive and aerospace sectors, where components are exposed to extreme temperatures without compromising performance. The application of industrial PTFE non stick coating involves advanced techniques to ensure uniform coverage even on complex industrial parts, with a thickness that can be adjusted to meet specific wear and performance requirements. Additionally, industrial PTFE non stick coating offers low friction properties, which reduces energy consumption in moving parts and minimizes wear and tear, extending the lifespan of industrial equipment. Whether used in precision manufacturing, chemical processing, or heavy machinery, industrial PTFE non stick coating is an indispensable solution that enhances operational efficiency, reduces maintenance needs, and ensures the longevity of industrial assets.