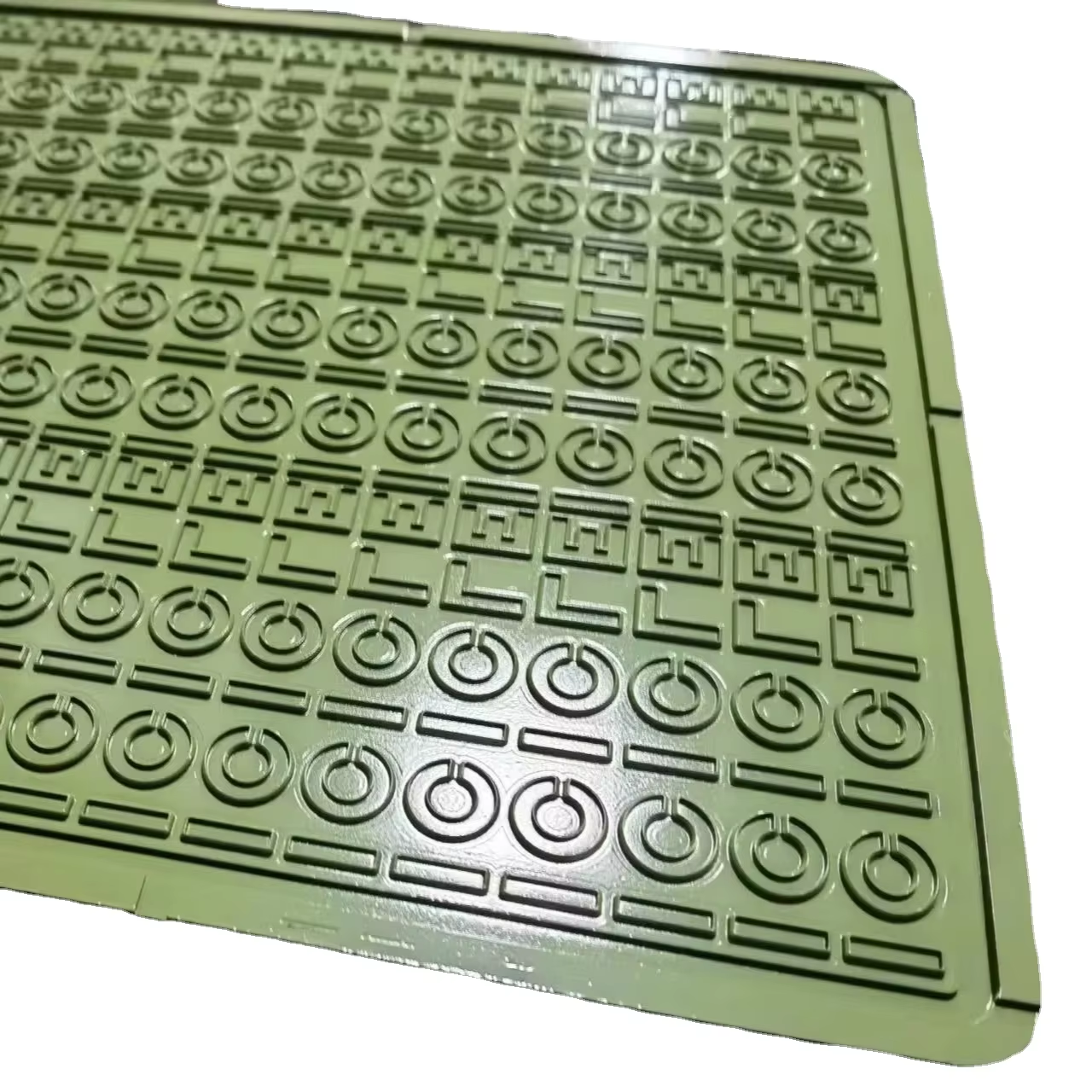

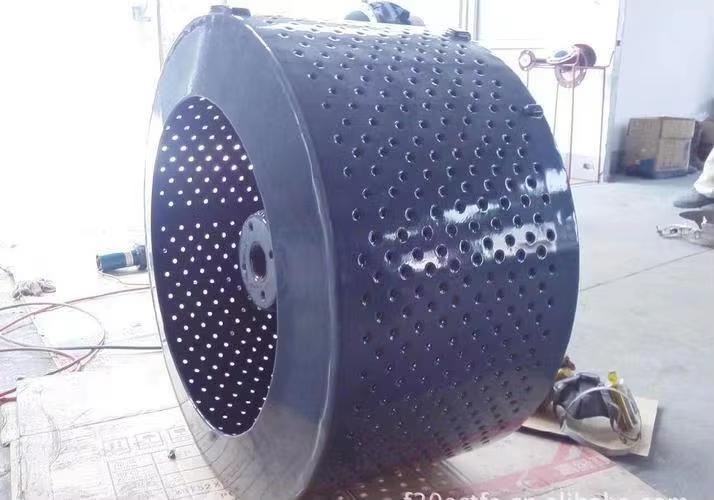

PTFE non stick coating for tanks is a highly specialized solution designed to revolutionize the performance and lifespan of tanks across various industries. This advanced PTFE non stick coating is meticulously engineered to form a robust and durable bond with tank substrates, which can include metals like steel, aluminum, as well as certain plastics and composites. By applying this PTFE non stick coating to the interior surfaces of tanks, it creates an ultra - smooth and non - adhesive barrier that effectively resists the adhesion of a wide range of substances. In the chemical industry, tanks often store aggressive and viscous chemicals. The PTFE non stick coating for tanks safeguards against corrosion caused by acids, alkalis, and solvents, preventing degradation of the tank material and ensuring the integrity of stored chemicals. This is crucial as any contamination or reaction due to a compromised tank surface could lead to safety hazards, product spoilage, or costly production disruptions. In the food and beverage sector, maintaining hygiene is of utmost importance. Tanks coated with PTFE non stick coating are easy to clean as residues from food products, such as syrups, sauces, or dairy substances, slide off effortlessly. This not only simplifies the cleaning process, reducing the need for harsh cleaning agents and excessive labor, but also helps in meeting strict food safety regulations by minimizing the risk of bacterial growth in hard - to - clean areas. For oil and gas storage tanks, the PTFE non stick coating for tanks prevents the build - up of wax, asphalt, and other hydrocarbons. This not only ensures the efficient flow of fluids during transportation and dispensing but also reduces the frequency of tank cleaning, which is often a time - consuming and expensive operation. The application process of PTFE non stick coating for tanks demands precision. Specialized techniques, such as spray coating or electrostatic deposition, are employed to guarantee uniform coverage even in complex tank geometries, including those with baffles, agitators, or multiple compartments. The coating's low coefficient of friction reduces the resistance to fluid movement within the tank, which can contribute to energy savings in pumping systems. Additionally, PTFE non stick coating for tanks exhibits excellent heat resistance, making it suitable for tanks used in high - temperature processes, such as those in the petrochemical industry where heated fluids are stored or transported. Overall, PTFE non stick coating for tanks is an essential solution for enhancing the functionality, safety, and cost - effectiveness of tank operations in diverse industrial settings.