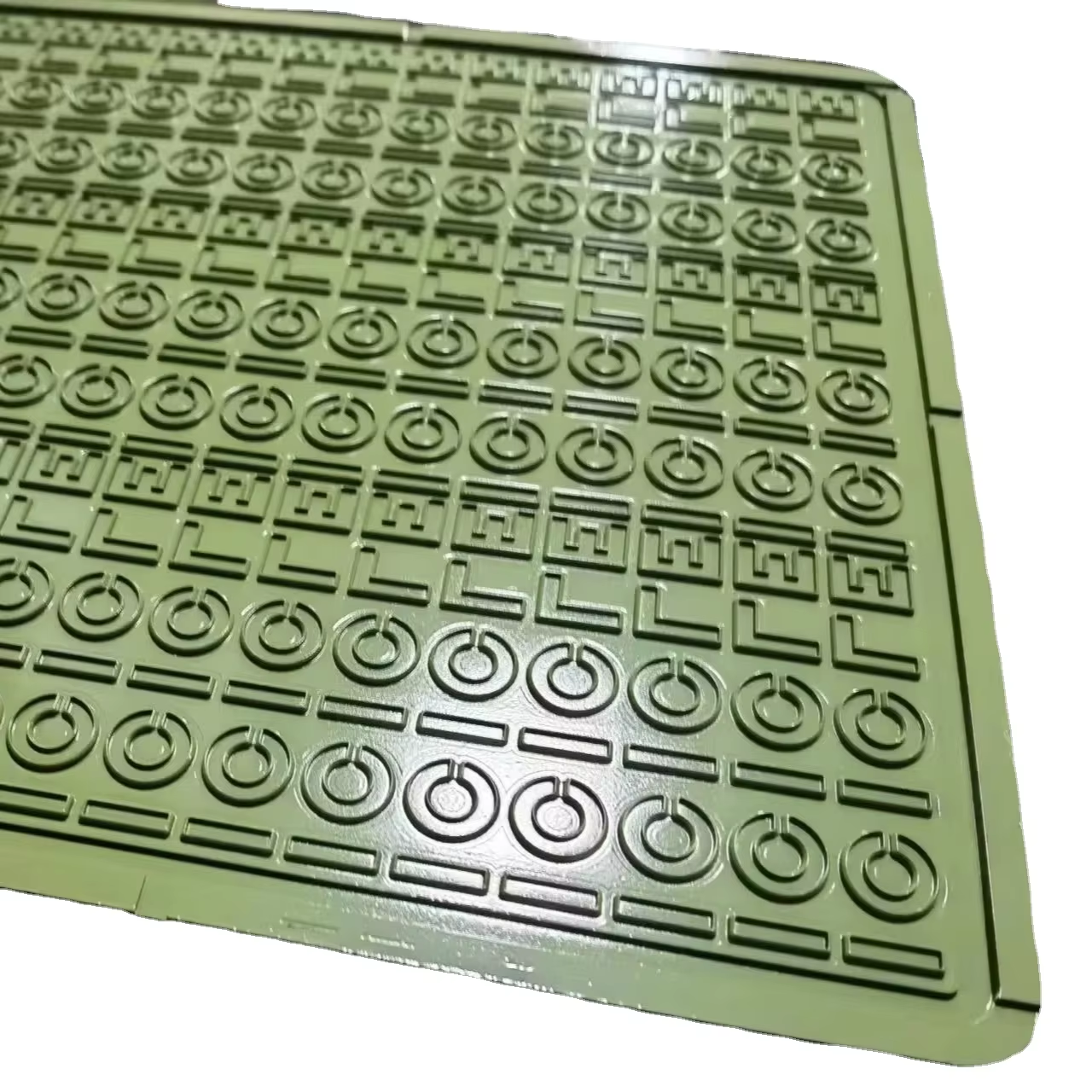

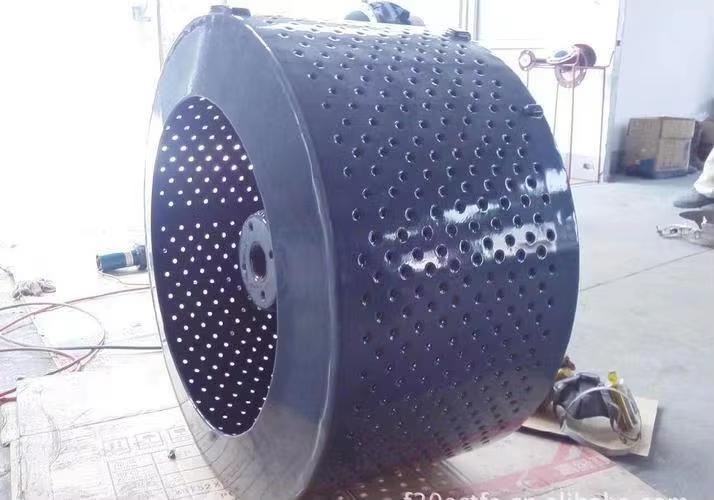

PTFE non stick coating for electronics is a specialized solution designed to meet the unique demands of electronic components, combining the precision requirements of electronics manufacturing with the non-stick and protective properties of PTFE. This PTFE non stick coating for electronics is engineered to form a thin, uniform layer on electronic parts such as connectors, circuit boards, sensors, and heat sinks, providing a barrier that resists the adhesion of dust, moisture, oils, and other contaminants, ensuring reliable performance and reducing the risk of malfunctions. PTFE non stick coating for electronics offers excellent dielectric properties, making it suitable for use on insulated components where electrical insulation is critical, preventing short circuits and maintaining signal integrity. In electronics manufacturing processes, such as soldering or assembly, PTFE non stick coating for electronics prevents the adhesion of flux, solder paste, and adhesives to tooling and fixtures, reducing cleanup time and extending the life of manufacturing equipment. This PTFE non stick coating for electronics also exhibits good heat resistance, withstanding the elevated temperatures encountered during thermal cycling, reflow soldering, and operation of high-power electronic devices, without degrading or losing its protective properties. The coating’s low coefficient of friction makes PTFE non stick coating for electronics ideal for moving electronic components, such as sliding contacts or switches, reducing wear and ensuring smooth operation over time. PTFE non stick coating for electronics is available in formulations that meet strict industry standards for outgassing, ensuring that it does not release volatile substances that could contaminate sensitive electronic components in enclosed environments, such as aerospace or medical devices. The application process for PTFE non stick coating for electronics involves precise methods, such as spray or dip coating, to ensure coverage of small, intricate parts without interfering with their functionality or electrical performance. Additionally, PTFE non stick coating for electronics provides chemical resistance, protecting components from damage caused by cleaning agents, coolants, and environmental pollutants, which is crucial for maintaining the longevity of electronic devices in harsh operating conditions. Whether used in consumer electronics, industrial control systems, or aerospace avionics, PTFE non stick coating for electronics enhances reliability, simplifies maintenance, and protects sensitive components, making it an invaluable solution in the electronics industry.