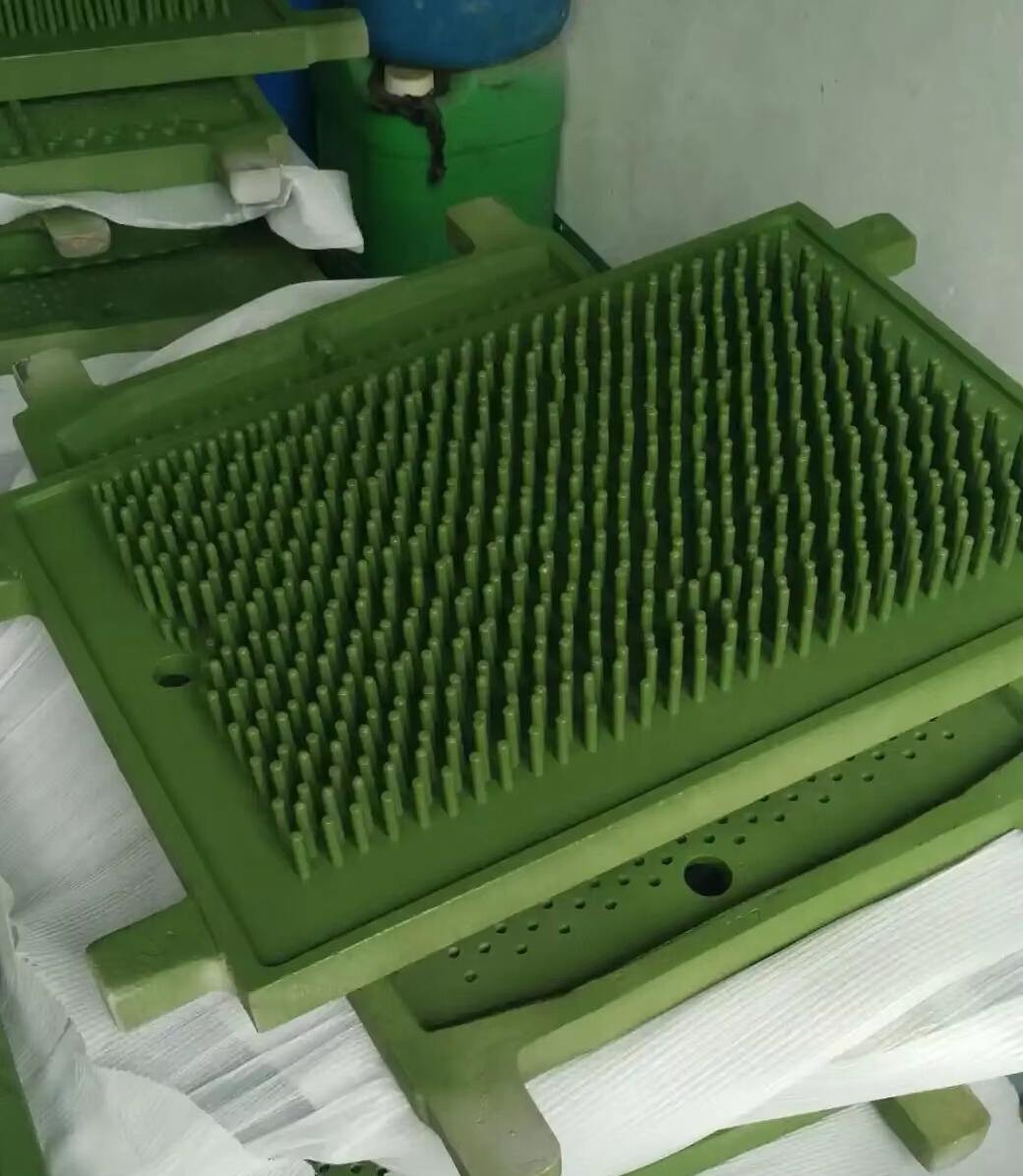

High Quality Anti-Stick Latex Pillow Mold Coating Durable PTFE Material Economically Priced for Spray Painting

- Overview

- Recommended Products

Product series |

Product Model |

Product Color |

Product Overview and Effects |

Product baking

temperature

|

Product baking time |

scope of application |

Teflon coating |

200 |

transparent |

Full gloss topcoat |

380°C |

About 50 minutes |

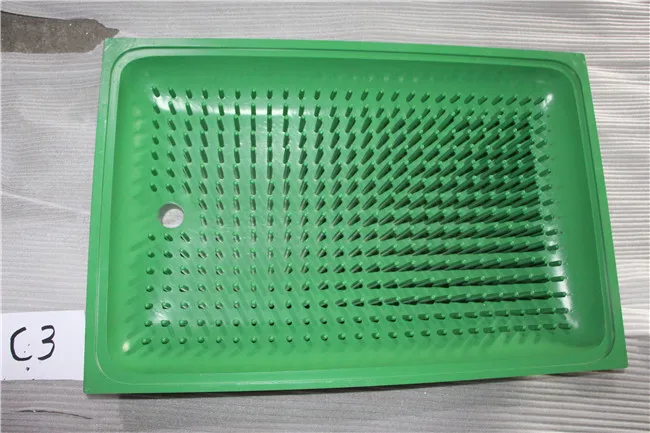

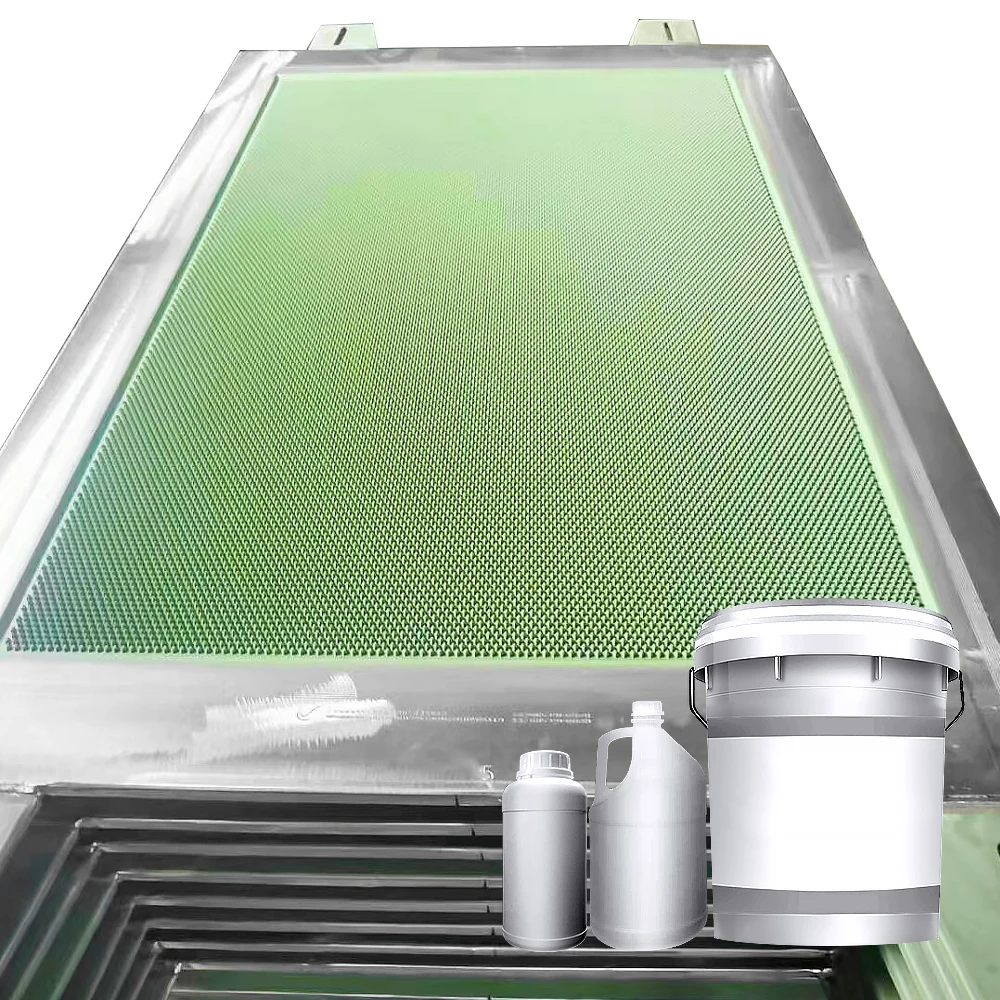

01. Textile guide roller 02. Textile drying drum 03. Wheel mold 04. Rubber mold 05. Sole mold 06. Heat exchanger 07. Tape guide roller 08. Rubber stopper mold 09. Copier roller 10. Industrial washing machine, drum 11. Various chemical equipment (reactor, agitator, mixing drum, box, valve, etc.) |

204 |

Green, black, gray |

Ordinary glossy topcoat |

||||

208 |

Green, black, gray |

Bright finish paint |

||||

214 |

Green, black, gray |

Mist finish paint |

||||

7799 |

red |

Primer additive |

||||

314 (primer) |

Green, black, gray |

Primer (two-component) |

200°C |

About 25 minutes |

||

316 (primer) |

Green, black, gray |

Primer (single component) |

||||

Room temperature self drying coating |

500 |

Transparent, milky white, green |

Natural curing (without baking) |

Room temperature

(self drying time about 45 hours)

|

Various types of rubber, plastic, metal products, molds, etc., such as fiberglass reinforced plastic, artificial stone, etc |

|

Nano double-layer coating (340 ° C series) |

Primer 518, Topcoat 519 |

black |

light |

340°C |

About 30 minutes (requires preheating spraying, temperature is about 50 ° C) |

Aluminum, stainless steel, ceramic cold plate, iron sheet, cast iron, etc; The ratio of topcoat to additives is 25:1 |

Nano non stick coating (280 ° C series) |

2600 Enhanced Series |

black |

light |

280°C |

About 30 minutes |

Aluminum, stainless steel, ceramic cold plate, iron sheet, cast iron, etc; Paint and spray gun should not come into contact with water |

Nano non stick coating (280 ° C series) |

128 series |

Various colors |

Bright, matte |

280°C |

About 30 minutes |

Aluminum, stainless steel, ceramic cold plate, iron sheet, cast iron, etc; Paint and spray gun should not come into contact with water |

Nano coating (280 ° C series) |

Three component coating |

Various colors |

Bright, matte |

280°C |

About 30 minutes of spraying money requires preheating for 9 hours and maturation |

Aluminum, stainless steel, ceramic cold plate, iron sheet, cast iron, etc; Various cooking utensils, etc |

Nano non stick coating (320 ° C series) |

8000 nanometer series |

transparent (YB-8000) grey (YB-8001) champagne (YB-8002) silvery (YB-8003) green (YB-8004) black (YB-8006) |

Bright, matte |

320 ° C

(gradually heating up)

|

About 30 minutes (requires preheating spraying, temperature is about 60 ° C) |

Aluminum, stainless steel, ceramic cold plate, iron sheet, cast iron, etc; Paint and spray gun should not come into contact with water |

Nano non stick coating (380 ° C series) |

138 series |

Various colors |

Bright, matte |

380°C |

About 30 minutes |

Aluminum, stainless steel, ceramic cold plate, iron sheet, cast iron, etc; Coatings and spray guns should not come into contact with water. It is recommended that the substrate metal reach a temperature of 50 ° C-60 ° C |

Multi functional water-based non stick coating |

Primer 8701 |

black |

Primer |

120°C |

About 25 minutes |

Aluminum, stainless steel, ceramic cold plate, iron sheet, cast iron, etc; Primer&Topcoat Cold Spray |

Topcoat 6902 |

black |

Topcoat paint |

380°C |

About 50 minutes |

||

|

Attention:

1. Before use, be sure to roll or shake the container to make the product uniform;

2. Please store the paint in a dry place (temperature around 5-29 ° C) and be careful to prevent freezing;

| ||||||

adhesion |

Level 0 (Hundred Grid Method) |

smell |

nothing |

Thermal Shock |

At 350 ° C/25 ° C, after 20 cycles,

there were no abnormalities in the coating.

|

Cold hardness/hot hardness |

≥ 4H (aluminum alloy, Mitsubishi pencil). |

Wear resistance |

Over 10000 times (with a load of 4.9 kilograms and a 3M scraping cloth) |

Corrosion resistance |

Soak the paint film in acid, 10% NaOH, solvent, water, and saline solution

at 70-80 ° C for 24 hours without any abnormalities.

|

non-stick |

Strong anti pollution properties for soy sauce, pigments, oils, and milk,

meeting the requirements for frying eggs and cooking

rice tests. |

Heat resistance |

> 500 ° C (long-term use temperature), > 700 ° C (short-term use temperature). |

Products Application

Products Application

1、Years of focus The company has been engaged in the non stick coating industry for many years, with a professional R&D team and sales team, which can solve common problems of PTFE for different customers.

1、Years of focus The company has been engaged in the non stick coating industry for many years, with a professional R&D team and sales team, which can solve common problems of PTFE for different customers.