Беспрецедентная антипригарная производительность

PTFE тұрақты емес қаптамалары өте төмен үйкелісі бар беттер жасайды, сондықтан нәрселер оларға жабыспайды, сондықтан оларды аспаздық қазан мен әртүрлі өнеркәсіптік машиналарда кеңінен пайдаланады. Зерттеулер осындай қаптамалар үйкелісті шамамен 80 пайызға дейін азайтып, жабдықтардың әртүрлі жағдайларда тиімді жұмыс істеуіне және ұзақ уақыт пайдалануына әкелетінін көрсетті. Пайдалану аясы тек құмыра мен қазанмен ғана шектелмейді. Өндірушілер өндіріс желілерінде материалдар біріне-бірі жабысып қалатын жерлерде PTFE-ге ауыртпалы түрде сүйенеді. Мұндай қаптама болмаса, зауыттарда жабдықтардың жұмысын тоқтату мен қалдықтарды шығындау проблемалары туындайды, әсіресе азық-түлік өңдеу зауыттары мен химиялық өндіріс кәсіпорындарында кішігірім қалдықтар уақыт өте келе үлкен проблемалар тудыруы мүмкін.

Үлкен температуралық ұшу

PTFE-нің қаптамасы өте ауыр температуралық жағдайларда жұмыс істей алады, ол минустің 450 градус Фаренгейттен 500 градус Фаренгейтке дейінгі температураларды қамтиды. Мұндай ыстыққа төзімділік осы қаптамалардың өте ыстық немесе суық болған кезде де тиімді болып қала беретінін білдіреді, бұл көпшілік материалдар жасай алмайтын нәрсе. Осындай тамаша қасиетіне байланысты, өнеркәсіптерде ешқандай жағдайда да істен шықпауы қажет жерлерде PTFE-ге сенім білдіріледі. Біз оны ұшақ двигателдерінен бастап автомобиль бөлшектеріне дейін, ыстықтың шектеусіз әсер ететін және адамдар шектеулерге дейін жеткізілген жағдайда ықтималдықпен қажет болатын материалдарды қолданады.

Химия және коррозияға қарсы қарым-қатынас

PTFE қаптамалардың ерекшелігі - олардың қышқылдар мен коррозияға өте төзімділігінде. Осыған байланысты олар коррозияның әсеріне ұшырайтын өндірістерде кеңінен қолданылады. Бұл қаптамалар агрессивті химикаттардың 90 пайызынан көбіне төзімді болып келеді, сондықтан уақыт өте келе техникалардың тозуынан қорғайтын қорғаныш қабаты ретінде қызмет етеді. Қатты химикаттармен әрдайым әсер етіп тұратын қондырғылар үшін мұндай қорғаныштың маңызы өте зор. Бұл жабдықтардың үздіксіз жұмыс істеуін қамтамасыз етеді, жөндеу шығындарын азайтады және машиналардың ауыстырылуына дейінгі пайдалану мерзімін ұзартады.

Санайы операциялардағы қызмет көрсету пайдері

Механикалық өсіру мен жұмсауға қарсы қорғау

ПТФЕ-мен қаптау өндірістік машиналардың уақыт өткен сайын тозуын айтарлықтай азайтады. Негізгі себебі: бұл қаптаулардың үйкелісі өте төмен, сондықтан металдық бөлшектер бір-біріне қатты әсер етпейді. Әртүрлі салалардағы зауыттар бұл қаптауларды пайдаланғаннан кейін жөндеу шығындарының төмендегенін және жабдықтардың бұрынғыдан әлдеқайда ұзақ қызмет ететінін байқады. Кейбір зерттеулерде ПТФЕ-мен қапталған машиналардың үйкелісінен 30 пайызға төмен тозатыны көрсетілген. Зауыт басшылары үшін бұл жөндеу аралықтарында жүйелердің тегіс жұмыс істеуін ұзартып, қосалқы бөлшектерді ауыстыру мен өнім шығару тоқтауларына кететін шығындарды үнемдеу дегенді білдіреді.

Үлгілеу тиесілігін беттерлеу

PTFE жабындар өндірісті жақсырақ жүргізуге көмектеседі, өйткені олар өндірісте ыңғайлы жұмыс істейтін беттер жасайды. Бөлшектердің арасындағы үйкеліс азайған сайын бүкіл процесстер жеңілдетіліп, цех аумағындағы жұмыстар тезірек орындала бастайды. Бұл кәсіпорындар үшін өнімдерді тезірек дайындауға мүмкіндік береді және басқа ештеңгені құртпайды. Бұны әртүрлі салалардан алынған нақты мысалдар да растайды. Бірнеше өндірушілер PTFE-мен жабылған жабдықтарды пайдалана бастағаннан кейін өндіру көлемі шамамен 20% артқанын хабарлады. Жылдамдықтан тыс, бұл тегіс беттер сериялар арасындағы сапаны біркелкі сақтауға көмектеседі. Дәл осындай тұрақсыз шығарындылар мен баяу айналу уақытымен күресіп жатқан басқа зауыттармен салыстырғанда осы тұрақтылық зауыттарға артықшылық береді.

Техникалық тоқтамаларды кемідікке алу

PTFE-нің өндірістік ортаға әкелетін пайдалы қасиеттері арнайы маңызды. Әсіресе, жабдықтардың жұмыс уақытын қысқарту мәселесін шешуге көмектеседі. Бұл қаптамалар өте берік және әртүрлі қатал жағдайларға төзімді болып келеді, яғни жабдықтар күтпеген уақытта бұзылмай әрі қарай жұмыс істей береді. PTFE қаптамаларға ауысқан өндірістік зауыттар жиі бұзылулардан үнемделген уақыттың қаптаманы жақтау шығындарын бірнеше ай ішінде өтейтінін хабарлайды. Кейбір зерттеулер PTFE қолданатын компанияларда күтпеген жабдықтардың шамамен 40% кеміп отырғанын көрсеткен, әрине нәтижелер қолдану сипатына байланысты өзгеруі мүмкін. Өндірістік жолдар үзіліссіз жұмыс істесе, зауыттар өз өнім шығару көлемдерін сақтап, бүкіл жеткізу тізбегін бұзып алмайтын қымбатқа тұратын кешігулерден құтылады.

Teflon Қатынасы Жүйелену Процессі және Қолдану Әдістері

Ерекше Көлемге Өзгерту Қатынасы Техникалары

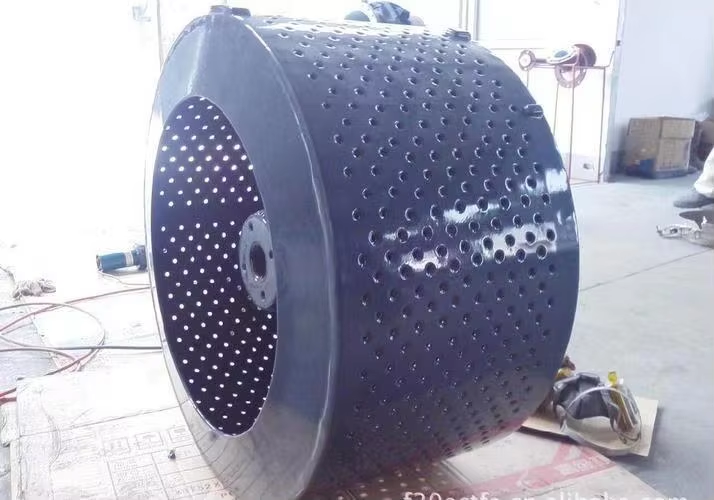

Біздің күнделікті жұмысымыздағы өнеркәсіптік беттерге PTFE немесе Тeflon барынша біркелкі жабу үшін бүріккіш қаптау әдісі шын мәнінде барлық айырмашылықты туғызады. Әдісті дұрыс орындау арқылы PTFE қажетті қолданысқа сәйкес тиісті түрде таралады. Бүріккіш қаптаудың икемділігі – бұл үлкен артықшылық. Құрылғының пішіні мен өлшемі қандай болса да, бұл әдіс өте жақсы жұмыс істейтіндіктен, әртүрлі салалардағы кәсіпорындар осы әдіске сеніммен сүйенеді. Зерттеулер басқа әдістерге қарағанда бүріккіш қаптау аздау саңылаулар мен ақаулар қалдыратынын көрсетіп отыр. Бұл беттердің бірікпейтін қасиеттерін сақтау және сонымен қатар үйкелістен қорғау үшін өте маңызды. Бүріккіш қаптауға ауысқан өндірушілердің көпшілігі бөлшектердің қаншалықты ұзақ қызмет ететінін және уақыт өте келе құрылғылардың жалпы өнімділігінің артқанын байқайды.

Температурлану процесінің оптимизациясы

Қатеу процесін дұрыс орындау PTFE қаптамаларының дұрыс жұмыс істеуіне әсер ететін барлығын анықтайды. Бұл маңызды кезеңде қаптама қандай болмасын бетіне бекітіледі, ол тікелей тефлонның уақыт өткен сайын қаншалықты тұрақты екенін анықтайды. Егер қатеу кезінде не температура тым жоғары немесе төмен болса, не уақыттың қатесі болса, қаптама дұрыс жабыспайды және түгелдей түсіп қалуы мүмкін. Көптеген өндірушілер жіберілген партиялармен тәжірибе алмасудан мұны біледі. Өндірушінің техникалық талаптарына қатаң сәйкес келу маңызды, өйткені дұрыс қатеу қаптамаға маңызды қасиеттер береді, мысалы, жылу зақымдануына қарсы тұру және химиялық заттарға төзімділік. Бұл құрылғылардың ұзақ уақыт қорғалып, қиын жағдайларда жақсы жұмыс істеуін білдіреді.

Қорынды имплементациясында сапа контролі

PTFE жабындарын қолданған кезде сапаны басқару олардың техникалық сипаттамаларына сай келуі үшін маңызды рөл атқарады. Өндірушілер жабын процесінің әртүрлі кезеңдерінде пайда болуы мүмкін ақауларды тексеруі қажет. Стандартты тест тәсілдері жабынның нақты жағдайларда қаншалықты тұрақты болатынын растауға көмектеседі. Бұл тестерге жабынның беттерге қаншалықты жабысатынын тексеру немесе оның тозуға қарсы кедергісін өлшеу қосылуы мүмкін. Компаниялар осы тәсілді жемқорлықпен қарастырған жағдайда болашақта қымбат тұратын істен шығуларды болдырмақ. Жабдықтар күтпеген тоқтауларсыз ұзақ уақыт жұмыс істейді, бұл жөндеу шығындарын үнемдеуге мүмкіндік береді. Ең бастысы, дұрыс қолданылған PTFE жабындар қызмет көрсету мерзімі бойы клиенттер күткен қорғанысты қамтамасыз етеді.

Экономикалық әсер және отрасельдік қолданбалар

PTFE қорындауларының құрмет-қарсы әnalысы

PTFE жабындарын қолдануды ойлаған кәсіпорындар алдымен кейбір есептеулер жүргізуге тиіс. Жөндеу жұмыстары сирегірек жүргізілетін және жабдықтар ұзақ қызмет ететін болғандықтан, тиімділік пен шығын арасындағы қатынасты талдау оларға үнемдеу мүмкіндіктері туралы түсінік береді. Зерттеулер бұл жабындарды қолданғаннан кейін бір немесе екі жыл ішінде көптеген компаниялар инвестицияларының қайтарылуын бастайтынын көрсетіп отыр. Неліктен? Өйткені жөндеу жұмыстарына кететін шығындар азаяды және жалпы алғанда операциялар тегіс орындалады. Мұндай бағалау жасаған кезде жабынды қолданудың бастапқы шығындарын және жөндеу жұмыстары өндірісті тоқтатып алмайтын болғандықтан пайда болатын үнемдеуді есепке алу маңызды. Сондай-ақ, жабдықтар ұзақ қызмет етіп, оларды ауыстыру қажеттілігі кешірек пайда болады. Барлық осы факторларды бірге есепке ала отырып, компаниялар бюджеттік шектеулерге сәйкес PTFE жабындарына шығын жасаудың және уақыт өткен сайын нақты пайда әкелетінін шеше алады.

Табиғаттың өңдеуі және пакеттеу шешімдері

PTFE-нің қаптамасы тамақ өңдеу саласында ластануды болдырмау және тазалауды жеңілдету үшін өте маңызды рөл атқарады. PTFE-нің жабыспайтын қасиетіне байланысты тамақты өңдеу мен тасымалдауды тиімді ұйымдастыруға мүмкіндік береді, себебі бұл беттерге өнімнің қалдығы аз түседі және жабдықтар ұзақ уақыт таза күйде қалады. Салада жүргізілген әртүрлі зерттеулерге сәйкес, бұл қаптамалар қазіргі кезде әңгіме жүргізіліп жатқан жоғары гигиена және тамақ өнімдерінің қауіпсіздігі стандарттарын сақтау бойынша айтарлықтай артықшылық береді. Олардың пайдалылығы беттерді таза және бактериялардан таза ұстауында, бұл қауіпсіздік ережелерін орындау мен тұтынушыларды қорғау үшін өте маңызды. Тамақ өңдеушілер жабдықтарына PTFE қаптамаларын орнатқан кезде, әдетте өндірістің жалпы тазалық деңгейі мен жұмыстың жылдамдығында жақсару байқалады.

Автомобилдерге қатысты компоненттерді сақтау системасы

Автомобиль саласында ПТФЭ-пен қаптау маңызды бөлшектерді тозу мен коррозиядан қорғауда маңызды рөл атқарады. Қолдану кезінде бұл қаптаулар цилиндр тұлғалары мен әртүрлі двигатель бөлшектері сияқты заттардың ұзақ қызмет етуін қамтамасыз етіп, қосымша автомобильдердің жұмыс істеу сапасын арттырады. Күнделікті двигательдермен айналысатын механиктер мен инженерлер қаптау өңделген бөлшектері бар автомобильдердің өнімдірек жұмыс істеп, ұзақ уақыт бойы сенімді болып қала беретінін көзбен көрген. Бұл бөлшектерді жиі ауыстыру қажеттілігінің болмауы автомобиль жасаушылар мен жүргізушілер үшін ұзақ мерзімде сервис орындарында үзілістерді және шығындарды азайтады. Сапасын арттыруды көздейтін автомобиль шығарушылар үшін ПТФЭ қорғанысын қосу экономикалық тұрғыдан да дұрыс, өйткені тұтынушылар сенімді автомобильдерді жылдан жылға шығарып тұратын брендтерді ұсыныс жасауға және қызмет көрсетуге қайта оралады.