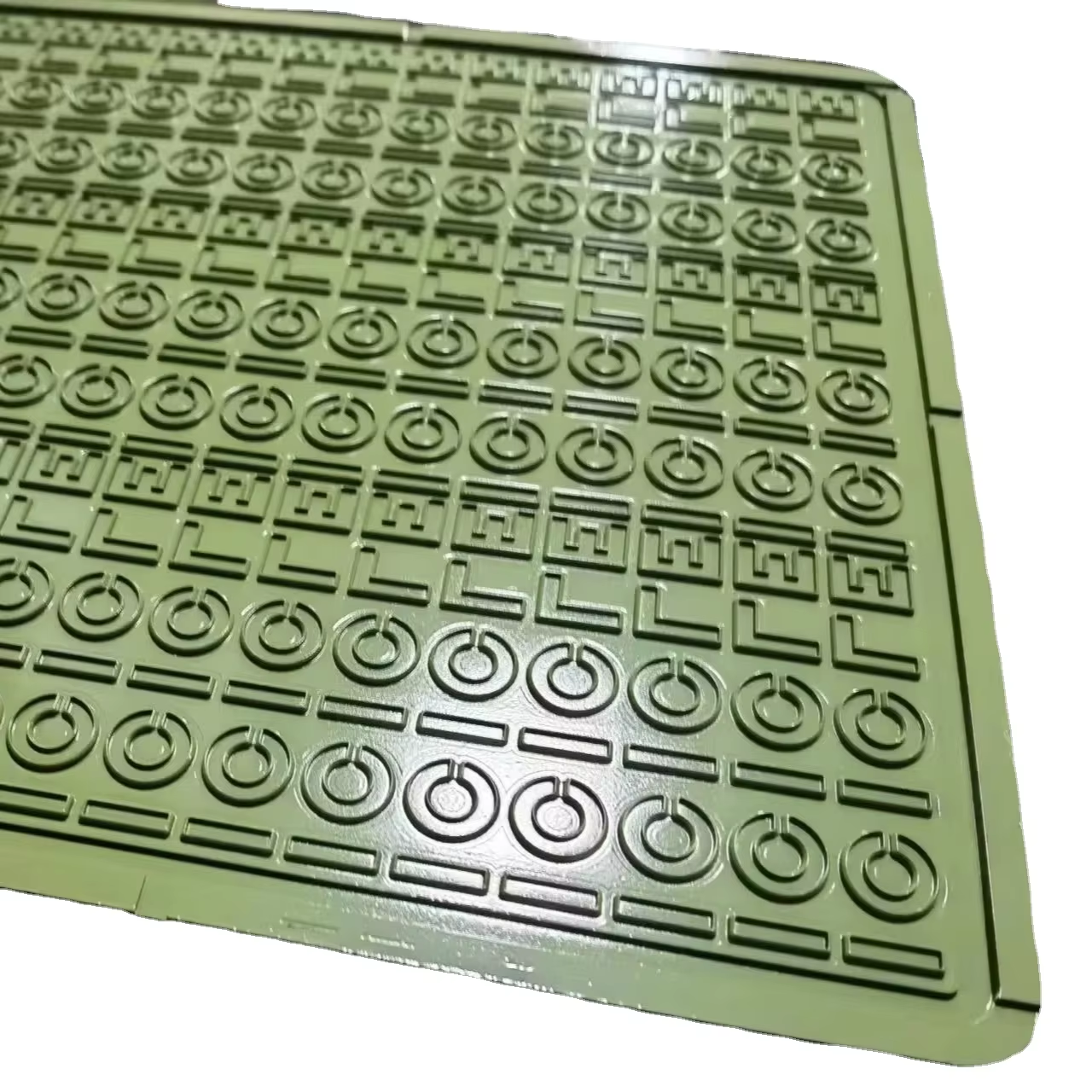

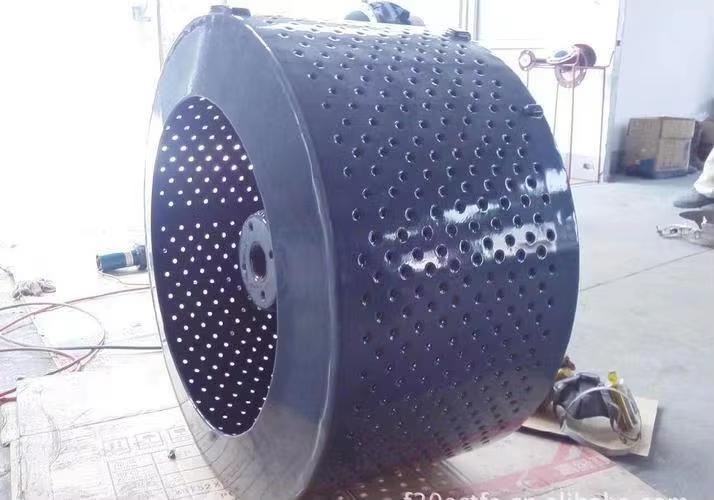

Wear resistant PTFE non stick coating is a high-performance formulation that combines the exceptional non-stick properties of PTFE with enhanced durability to withstand abrasion and friction, making it ideal for applications where both non-stick functionality and resistance to wear are critical. This wear resistant PTFE non stick coating is engineered with reinforcing additives that strengthen the coating matrix, allowing it to endure repeated contact with hard or abrasive materials without losing its non-stick properties or breaking down. Wear resistant PTFE non stick coating is widely used in industrial machinery, such as conveyor belts, chutes, and hoppers, where materials are transported and the coating must resist abrasion from granular or sharp-edged substances while preventing adhesion. In manufacturing processes involving molds, such as plastic injection or rubber molding, wear resistant PTFE non stick coating extends the life of molds by withstanding the repeated stress of part release and reducing friction between the mold and the molded material. This wear resistant PTFE non stick coating also finds applications in food processing equipment, such as mixers, blenders, and processing blades, where it resists wear from food particles and cleaning processes while maintaining easy release and hygiene standards. The wear resistance of this PTFE coating is complemented by its excellent chemical resistance, protecting surfaces from corrosion caused by cleaning agents, industrial fluids, and food acids, ensuring long-term performance in diverse environments. Wear resistant PTFE non stick coating can be applied to various substrates, including metals, ceramics, and composites, with strong adhesion that prevents peeling or flaking even under heavy use. The coating maintains its non-stick properties even after prolonged wear, ensuring consistent performance and reducing the need for frequent reapplication. For high-traffic components, such as bearings, gears, and sliding surfaces, wear resistant PTFE non stick coating reduces friction-induced wear, lowering maintenance costs and extending the operational life of the equipment. This coating is also suitable for use in harsh environments, including those with high temperatures or exposure to UV radiation, without compromising its wear resistance or non-stick functionality. Whether in industrial, food processing, or manufacturing settings, wear resistant PTFE non stick coating delivers a durable, high-performance solution that combines the best of non-stick and wear-resistant properties, making it a valuable asset for enhancing equipment performance and longevity.