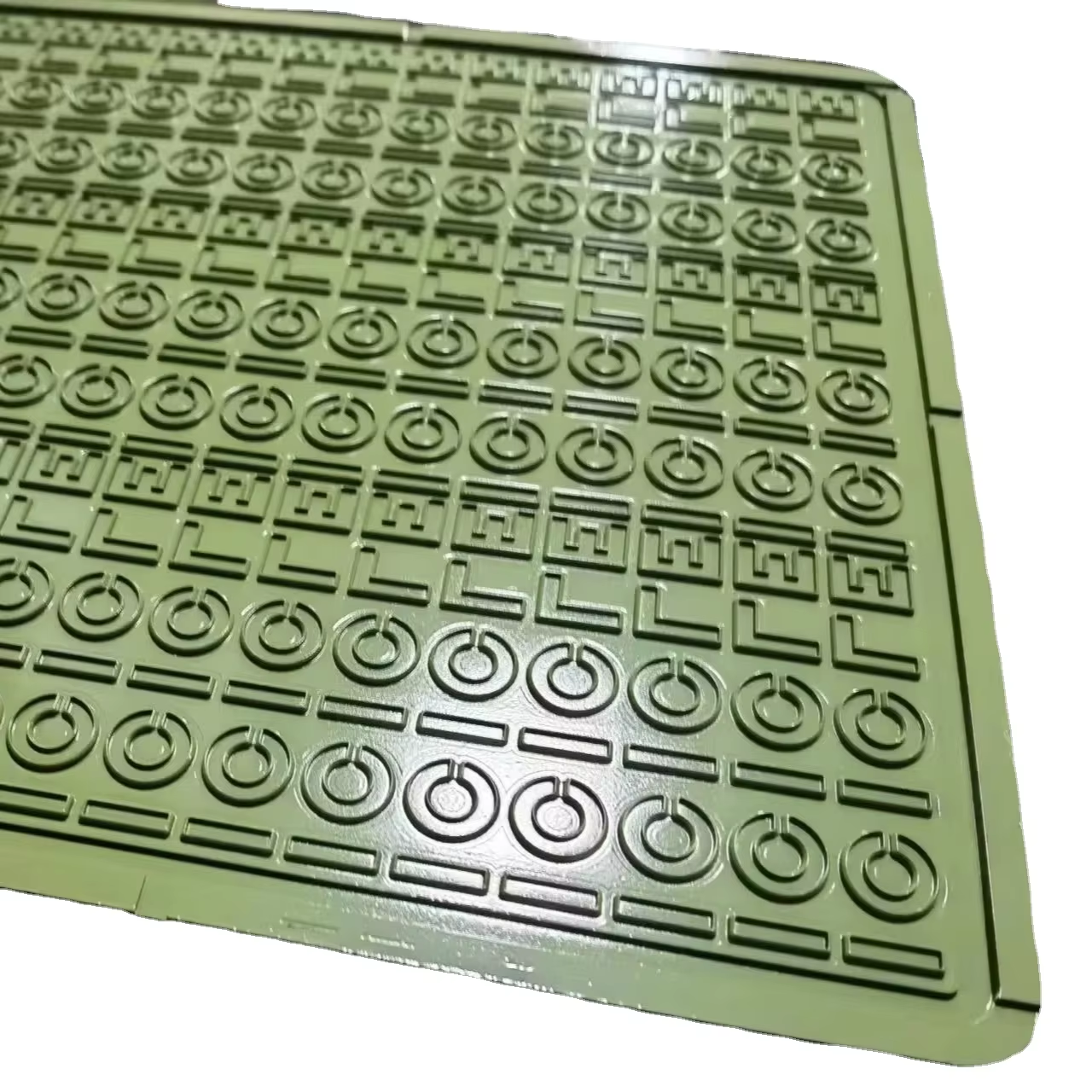

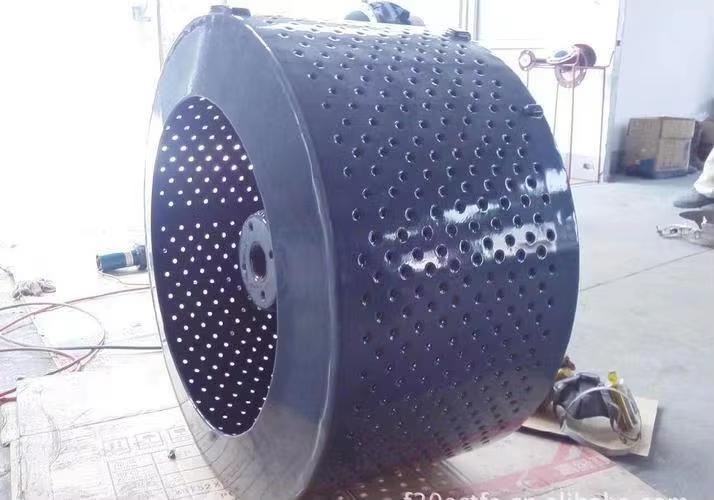

Our PTFE non-stick coating for pumps is expertly designed to address the unique challenges of pump components, enhancing their performance and longevity. Engineered to create a smooth, non-adhesive surface on impellers, casings, and other internal parts, this coating minimizes the adhesion of sediments, viscous fluids, and particulates, reducing friction and preventing clogging. The PTFE formulation offers exceptional chemical resistance, safeguarding pump components from corrosion caused by aggressive liquids, acids, and alkalis, thus extending the service life of the pump. Its high-temperature resistance ensures the coating remains stable even under extreme operating temperatures, making it ideal for use in chemical processing, petroleum, and wastewater treatment applications. Applied via a precise spray method, the coating forms a uniform, thin layer that adheres firmly to metal surfaces without compromising the pump's hydraulic efficiency. This non-stick solution not only improves the flow of fluids through the pump but also reduces energy consumption and maintenance costs by minimizing the need for frequent disassembly and cleaning. Compliant with FDA and SGS standards, it is safe for use in food and pharmaceutical industries. With its anti-wear and anti-scratch properties, the coating further protects pump components from mechanical damage, ensuring reliable and efficient operation over time.