As custom manufacturing progresses, the inclusion of rubber molds offers unrivaled adaptability and efficiency. This blog focuses on the evolving role of rubber molds, their applications, and the ways in which they impact the manufacturing industry.

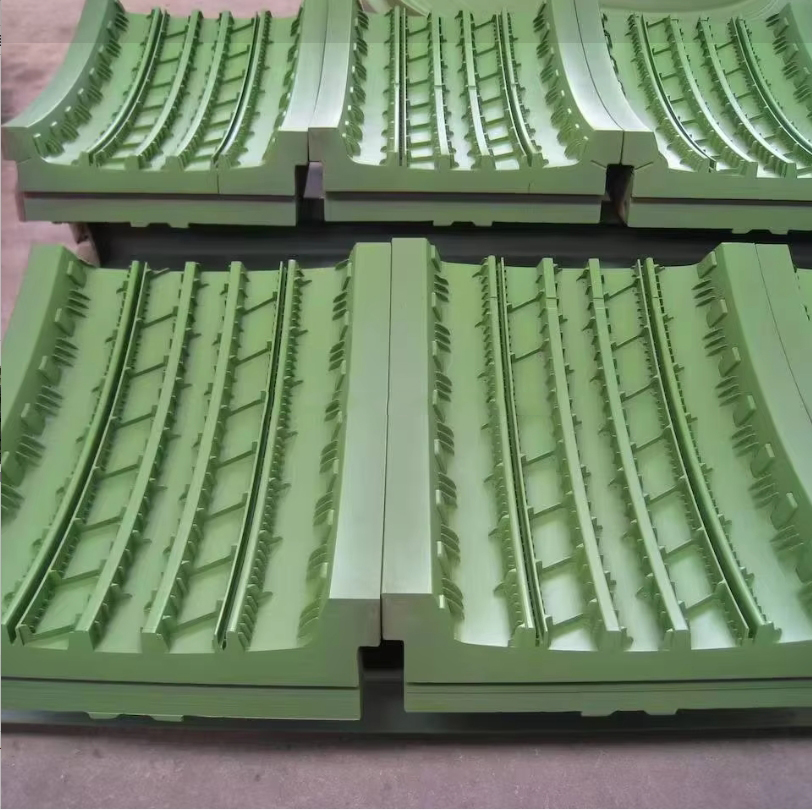

What Are Rubber Molds?

Rubber molds are critical components of custom manufacturing, which aid in the precise realization of intricate designs and shapes. Their production cost is lower than the industry standards, alongside their efficiency in meeting production demands, which makes them beneficial in emerging markets. Due to the continuos innovations in various and emerging industries, the future demand for rubber molds is going to be incredibly high.

Uses of Rubber Molds in Different Industries

Rubber molds are used in various sectors, including automotive, aerospace, and consumer goods sectors. For instance, in the automotive sector, rubber molds are employed in the production of gaskets, seals, and other components with high durability and flexibility. These molds are also employed in the aerospace industry for the production of light, strong, and safe components. The ability for manufacturers to be able to meet diverse custom manufacturing needs clearly shows the importance of rubber molds.

Benefits of Rubber Molds

Rubber molds are beneficial in manufacturing because they can withstand high temperature and pressure. This characteristic is suited for many manufacturing processes. Apart from that, rubber molds can be reused many times, which greatly lowers production costs. Also, manufacturers can swiftly meet market changes because they can quickly adjust molds to any customization. In addition, rubber molds can capture intricacies which ensures that high quality is maintained throughout the production of the final goods.

Modernization of Rubber Molds Techniques

Other than manufacturing processes, the future of rubber molds is being shaped by technological advancements to processes like 3D printing and CAD (Computer Aided Design). These changes to the cycle of mold creation bring speed and precision into the manufacturing. Hence, the time to market the products is much sooner than it was in the past. In addition, changes in the field of materials science are creating new rubber compounds that are and which will greatly improve the technological capabilities of rubber molds.

Industry Trends and Future Outlook

As for the future, the rubber mold manufacturing sector is set to expand. To enhance operational efficiency, businesses are looking for sustainable manufacturing practices which make use of renewable resources and reduce energy expenditure. Automation and smart manufacturing are also set to enhance the efficiency of rubber mold production. Alongside the changes in the industries, it is interesting to see the evolving importance of rubber molds in bespoke manufacturing, which will in turn create new opportunities and innovative solutions.

In summary, technological innovation and a rising need for bespoke solutions has set a promising future for rubber molds in custom manufacturing. Increased adaptability by the manufacturers will result in rubber molds concurrently meeting a wider range of custom demands.