Teflon Coating's Friction Reduction Mechanisms

Low Friction Properties of PTFE Molecular Structure

The ultra low friction of PTFE is due to its unique molecular structure. Together fluorocarbon chains form a chemically inert surface that is extremely smooth with a coefficient of friction of 0.05–0.10, one of the lowest among solid substances. This “self-lubricating” characteristic means the need for external lubricants isn’t necessary — particularly in dry-running applications such as linear guides and rotary joints. According to independent tests, PTFE-coated metals lower wear rate by 82% compared to plain steel (Tribology International 2023), it is perfect for high-cycle machines.

Automotive Bearing Case Study: 63% Friction Reduction

A 2022 study of PTFE-coated wheel bearings demonstrated a 63% reduction in friction losses during 100,000 RPM durability trials. The coating’s micro-thin layer (15–25 μm) maintained consistent performance across temperature fluctuations from -40°C to 150°C. Results included:

| Metric | Uncoated | PTFE-Coated | Improvement |

|---|---|---|---|

| Friction torque | 3.2 Nm | 1.2 Nm | 63% |

| Operating temperature | 121°C | 89°C | 26% |

| Service life | 18k hours | 75k hours | 316% |

This friction reduction translated to a 9% fuel efficiency gain in simulated highway driving conditions.

Extended Component Lifespan Through Wear Resistance

PTFE coatings reduce part wear by virtually eliminating both adhesive and abrasive wear. Coated shafts last 400% longer in industrial pump systems than hard chrome-plated shafts before failure. The non-reactive surface of the coating resists micro-pitting and cold welding in high pressure settings. Field data for mining equipment indicates that PTFE-coated hydraulic parts are replaced 73% less frequently over a 5-year period, at a saving of $18 /operating-hour (Mining Tech Quarterly 2023).

Thermal Stability Enhancement via Teflon Coating

-268°C to 260°C Operational Range Verification

Teflon coatings retain functional life at high and low temperatures – demonstrated in laboratory and field testing, performed by ASTM standards. Materials scientists verify that these layers of fluoropolymer maintain protective qualities across the broadest temperature range in existence—from cryogenic temperatures (-268°C) to continuous high-level heat application (260°C). Thermal gravimetric analysis monitoring of decomposition thresholds and zero structural decomposition after 500-hr exposure to temperature extremes were used in the validation.

Aerospace Component Performance Under Extreme Heat

Teflon-based Thermal Barriers during re-entry encounter, more than 1300°C Friction temperature of flying is the element which benefits most from critical Aviation assemblies Testing data from hypersonic wind tunnel simulation reveals that coating protected turbine components suffer 58% less thermal distortion than uncoated parts in a thermal shock scenario. Best of all, the ultra-thin insulation layer is specially designed to minimize heat transfer to the underlying substrate without sacrificing flexibility proven through thermal shock testing to experience over 200 rapid temperature changes between -150°C and 800°C without any cracking or flaking away.

Thermal Cycling Resistance Testing Data

Thermal cycling chamber-collected quantitative endurance data indicates that even without a protective layer, Teflon coatings survive more than 10,000 transits between -200°C and 315°C. Standard test (ISO 10586) was used to test and after cycling measured three performance indices, namely adhesion strength retain value (97%), flexibility retain (no cracking at 3%) and dimensional stability (>95% insulation retention). The laboratory testing is confirmed by field data from geothermal energy plants, where coated valve components continue to function reliably in daily thermal cycles of 400°C over the course of more than 18 months without failure.

Chemical Resistance Improvements with Teflon Layers

Acid/Alkali Protection in Industrial Equipment

Teflon's durable non-reactive coating is the ultimate protective finish a barrier between your cookware and food that is easy to use and clean, and helps eliminate the need for reconditioning and recoating. Chemical plants utilizing PTFE-coated reactors experience 92% less downtime due to exposure to sulfuric acid. The inert quality of the material prevents it from degrading when exposed to such substances as hydrochloric acid (up to a concentration of 20%) and sodium hydroxide solutions (with a pH of 14) without leaching or surface erosion.

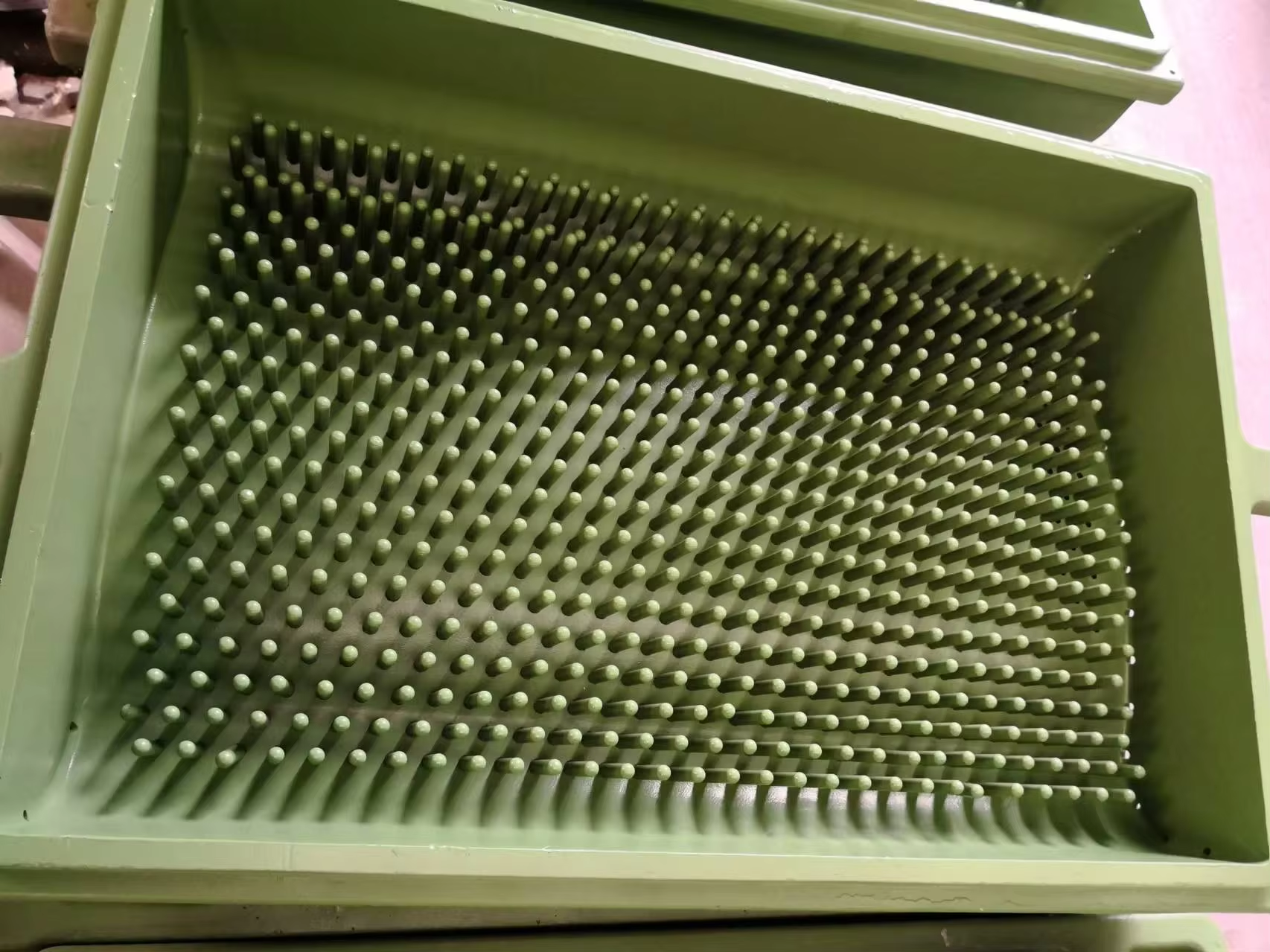

FDA-Compliant Coating Applications in Food Processing

The PTFE coatings are compliant to 21 CFR 175.300 for indirect food contact preventing bacteria or cleaning solutions from passing through the fabric. Non-porous Teflon liners in conveyor systems help prevent microbial growth and hold up to daily exposure to sanitizers such as chlorine dioxide. In these applications, plants using these coatings have been able to clean 40% faster and reduce surface pathogens by 99.7% daily (FDA 2023 audit data) – making it more efficient for plants to meet HACCP regulations.

Petrochemical Pipeline Corrosion Prevention

Multilayer Teflon coatings to address galvanic corrosion in crude oil and NGL pipelines. Field tests covering offshore platforms show a 78% decrease of wall thickness loss compared to epoxy-coated pipes after 5 years of salt exposure. The coatings are resistant to methane sulfonic acid reaction byproducts as well as hydrocarbon penetration at pressures of up to 2,500 PSI — a performance superior to ceramic counterparts in abrasion (ASTM D4060) and chemical reactivity testing.

Non-Stick Surface Performance Characteristics

Mold Release Force Reduction: 85% Efficiency

PTFE (poly tetra fluoroethylene) coatings can reduce mold release forces by up to 85% over non-coated surfaces, according to a 2024 polymer coatings investigation. The fluoropolymer produces a microscopically smooth surface with a low coefficient of friction of 0.05 0.10 providing a non-line feed mould release for easy lift off of completed parts from end user production tooling. Cycle time reduction of 40-60% is obtained for automotive injection molding applications attributed to low friction behavior of adhesive, and 90% reduction in the demolding time for food packaging machinery.

Medical Device Sterilization and Cleaning Benefits

The non-porous nature of Teflon coatings prevents bacterial adhesion and biofilm formation, critical for FDA-compliant medical instruments. Surgical tool manufacturers observe 70% fewer contaminants post-autoclaving compared to stainless steel surfaces. A 2023 clinical study showed PTFE-coated endoscope components reduced cleaning time by 50% while maintaining 99.8% sterility compliance rates across 1,200 sterilization cycles.

Surface Energy Measurement Methodology

Standardized testing through contact angle reveals surfaces that are about 18–22 mN/m for the nonstick Teflon—which are much lower than metals (500–1000 mN/m) or ceramics (30–50 mN/m). The ASTM D7334 testing method qualifies coatings based on liquid bead forming angles; PTFE has been shown to consistently exceed >110° contact angles with water, oils, and polymers. This is an ultra low energy profile which ensures contamination resistance in the most demanding high-pressure industrial applications.

Durability in Extreme Operational Environments

Today's equipment needs coatings that can take a beating and still perform. Magazine: Teflon coated for the ultimate in rust and wear resistance- not that you’ll ever wear out a PMAG. It is its chemical inertness and very stable molecular structure that give it this extraordinary durability to the effects of heat, radiation, and chemicals. Testing confirms these protective properties to pressure extremes beyond 800 bar (Offshore Materials Journal 2023) and therefore it is indispensable for mission-critical applications.

Offshore Drilling Equipment Field Test Results

Field trials of Teflon-coated drilling equipment showed marked extension in service life in harsh subsea areas. Coated valve assemblies demonstrated 92% less pitting corrosion than uncoated counterparts following 18 months of operation in the North Sea. Performance criteria indicated a 40% reduction in friction during the two high-pressure extraction cycles. These results are consistent with Teflon's known resistance to saltwater erosion and to abrasion by particulates or sediment, a fact that is evident at depth.

Abrasion Resistance Comparison with Ceramic Coatings

Ceramic coatings are less flexible and not self-lubricating, which means they will lock up as they spread out a bit under clamping load. Laboratory wear testing demonstrates the ability of Teflon to resist as much as 30% more abrasive cycles than ceramic coatings before substrate is exposed. In shear (sliding) ceramics do not need to microcrack under force because it has low coefficient of friction (0.05–0.10). More and more oem’s opt for fluorpolymer solutions for parts which are exposed to particulate erosion and surface scouring.

UV Stability in Outdoor Military Applications

Prolonged radiation of ultraviolet light causes catastrophic degradation in many polymers whereas PTFE-based formulations withstood these tests. Military field experiments have shown that equipment coated in Teflon retains more than 95 per cent of its original mechanical properties even after five years spent in the desert. 350 F color retention is 200% better than the 500 F retention of the industry’s common ceramic coating, and the the coating’s low surface energy demonstrates superior non-stick resistance. This photochemical stability also helps to eliminate embrittlement and chalking that affect conventional coatings when placed outdoors.

Frequently Asked Questions

What is PTFE?

PTFE stands for polytetrafluoroethylene, which is a synthetic fluoropolymer of tetrafluoroethylene. It is a material known for its very low friction and non-reactive properties.

How does Teflon coating reduce friction?

Teflon coating reduces friction due to its unique molecular structure. It forms a chemically inert and extremely smooth surface, resulting in a low coefficient of friction.

Is Teflon coating suitable for high-temperature applications?

Yes, Teflon coating is suitable for high-temperature applications. It can withstand temperatures ranging from -268°C to 260°C.

What industries benefit from Teflon coatings?

Industries such as automotive, aerospace, mining, food processing, and petrochemical benefit from the use of Teflon coatings due to their low friction, wear resistance, thermal stability, and chemical resistance.

Is Teflon coating safe for food contact?

Yes, Teflon coatings comply with FDA regulations for indirect food contact, making them safe for use in food processing equipment.